Why Traditional Commercial Epoxy Flooring Fails in High-Traffic Environments

Most commercial flooring materials were designed for a different era—when foot traffic was lighter, cleaning protocols were less aggressive, and businesses could afford to close sections for regular maintenance. Today’s commercial environments demand more, and traditional solutions consistently fall short in ways that cost businesses thousands of dollars annually.

The hidden costs of vinyl composite tile (VCT) become apparent within the first year. Despite being inexpensive to purchase, VCT requires professional stripping and waxing every few months, costing Vancouver businesses an average of $2,500-$4,500 annually for a typical 5,000 square foot space. The seams between tiles collect dirt, bacteria, and moisture, creating hygiene problems that are particularly problematic in healthcare settings and food service areas.

Ceramic and porcelain tiles present their own challenges in high-traffic settings. Grout lines become maintenance nightmares, requiring frequent cleaning and periodic replacement. When tiles crack under impact—common in institutional and industrial settings—the repair process often requires removing multiple tiles, leading to mismatched patches and extended downtime.

Carpet in commercial environments creates an entirely different set of problems. Beyond obvious staining and wear patterns, carpet harbors allergens, odors, and bacteria that compromise indoor air quality. Replacement costs every 3-5 years, combined with frequent deep cleaning requirements, make carpet one of the most expensive flooring choices over time.

Concrete floors, while durable, present their own issues when left unprotected. Concrete is naturally porous, absorbing spills and stains permanently. The surface dusts continuously, requiring frequent cleaning while never achieving the clean, professional appearance that modern businesses require. In Vancouver’s wet climate, unprotected concrete can develop serious moisture-related problems that compromise both appearance and structural integrity.

These traditional solutions all share common failure points: they have seams where dirt and moisture accumulate, they require intensive maintenance regimens, they show wear patterns quickly, and they need complete replacement much sooner than businesses anticipate. Modern epoxy flooring systems eliminate these problems entirely.

The High-Performance Epoxy Advantage: Engineering Solutions for Real-World Problems

High-performance epoxy flooring represents a fundamental shift from cosmetic surface treatments to engineered systems designed to solve specific commercial challenges. These aren’t the basic garage floor coatings most people associate with epoxy—they’re sophisticated polymer systems that can be customized for each facility’s unique requirements.

Seamless construction eliminates the maintenance nightmares associated with traditional flooring. When properly installed by experts like Fraser Plus Epoxy, high-grade commercial epoxy creates a monolithic surface with no seams, joints, or grout lines where dirt and bacteria can accumulate. This seamless design is particularly valuable in healthcare settings, where infection control protocols require surfaces that can be thoroughly sanitized without harboring contaminants.

The molecular structure of modern epoxy resins creates exceptional durability characteristics. Unlike surface coatings that can scratch or wear away, properly formulated epoxy penetrates into the concrete substrate, creating a chemical bond that actually strengthens the underlying floor. This integrated approach means that wear patterns don’t expose weaker underlying materials—the entire thickness of the coating maintains consistent performance properties.

Chemical resistance capabilities have advanced dramatically in 2025 formulations. Leading commercial epoxy systems can withstand exposure to acids, bases, solvents, oils, and cleaning chemicals that would quickly damage traditional flooring materials. For Vancouver’s diverse commercial sectors—from food processing facilities in Richmond to automotive service centers in Burnaby—this chemical resistance translates to decades of reliable performance without degradation.

Impact resistance is another critical advantage. Modern epoxy formulations include flexible polymers that absorb shock rather than cracking under point loads. When a heavy tool drops onto an epoxy floor, the surface may show a minor mark but typically doesn’t crack or chip like brittle materials. This resilience is particularly valuable in warehouse and industrial settings where equipment impacts are inevitable.

The slip-resistance properties can be engineered into the flooring system during installation. By incorporating specific aggregate materials or texturing techniques, installers can create surfaces that provide appropriate traction for each environment—from the subtle texture needed in office buildings to the aggressive slip-resistance required in commercial kitchens or wet processing areas.

Solving the Big Three: Preventing Blistering, UV Damage, and Delamination

The most common epoxy flooring failures—blistering, UV damage, and delamination—aren’t inherent problems with epoxy itself. They’re the result of improper installation techniques, inadequate surface preparation, or using the wrong system for specific environmental conditions. Understanding and preventing these issues is crucial for long-term success.

Blistering and bubbling typically occur when moisture vapor or air becomes trapped beneath the epoxy coating. In Vancouver’s climate, with frequent rain and high humidity levels, moisture management is particularly critical. Professional installation begins with comprehensive moisture testing using calcium chloride tests and relative humidity probes to ensure concrete substrates are sufficiently dry for epoxy application.

Modern moisture mitigation techniques include specialized primer systems that penetrate deeply into concrete, sealing microscopic pores that could allow vapor transmission. When dealing with problematic concrete slabs, experienced contractors may apply moisture vapor barriers before the epoxy system, ensuring long-term adhesion even in challenging conditions.

UV degradation has historically been epoxy’s Achilles heel, particularly in areas with large windows or skylights. Traditional epoxy resins yellow and chalk when exposed to sunlight, compromising both appearance and performance. The 2025 solution involves hybrid coating systems that combine epoxy’s excellent adhesion and chemical resistance with polyaspartic or polyurethane topcoats that provide superior UV stability.

These advanced topcoat systems maintain their clarity and color stability even under direct sunlight exposure. For Vancouver commercial spaces with significant natural light—like showrooms or retail environments—UV-stable coatings ensure that floors maintain their intended appearance for decades rather than requiring replacement due to discoloration.

Delamination prevention centers on achieving optimal surface profile and contamination removal. Professional surface preparation involves diamond grinding to create the correct anchor profile, followed by thorough removal of all dust, oils, and chemical residues that could interfere with adhesion. Advanced cleaning protocols may include acid etching, degreasing, and even shot blasting for heavily contaminated surfaces.

The latest epoxy formulations include improved wetting agents that help the coating penetrate into surface irregularities, maximizing mechanical bonding. Some systems also incorporate chemical bonding agents that react with concrete calcium hydroxide, creating both mechanical and chemical adhesion for superior long-term performance.

Quality control procedures now include pull-off adhesion testing before project completion. This quantitative testing verifies that the installe d coating meets or exceeds specified adhesion standards, providing objective evidence of installation quality and long-term reliability.

Temperature control during installation has become increasingly sophisticated. Vancouver’s variable climate conditions require careful timing and environmental controls to ensure proper curing. Professional installers monitor ambient temperature, humidity levels, and surface temperatures throughout the installation process, sometimes using temporary climate control systems to maintain optimal conditions.

Substrate evaluation now includes advanced testing for concrete density, porosity, and contamination levels. This comprehensive assessment allows installers to select the appropriate primer and coating system for each specific substrate condition, dramatically reducing the likelihood of adhesion failures that plague improperly specified installations.

Cost Analysis: The True Economics of Commercial Epoxy Flooring

The financial advantages of high-performance epoxy flooring become clear when examining total cost of ownership rather than just initial installation expenses. Vancouver businesses that have made the switch report maintenance cost reductions of 60-80% compared to traditional flooring systems, with some facilities eliminating floor-related maintenance entirely for years at a time.

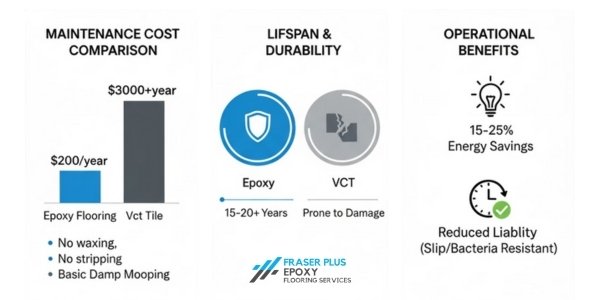

Maintenance cost comparisons reveal dramatic differences over time. A typical VCT installation requires professional maintenance every 3-4 months at approximately $0.50-$0.75 per square foot, plus complete replacement every 7-10 years. Over 20 years, a 5,000 square foot commercial space with VCT will incur maintenance costs exceeding $30,000, not including replacement expenses.

In contrast, properly installed commercial epoxy requires only basic cleaning with standard janitorial equipment and supplies. No waxing, no stripping, no tile replacement—just daily sweeping and occasional damp mopping. Annual maintenance costs typically drop to under $200 for the same 5,000 square foot space, creating cumulative savings that far exceed the initial investment premium.

Energy efficiency benefits add another layer of cost savings. Epoxy’s smooth, reflective surface improves light distribution, reducing lighting requirements by 15-25% in typical commercial environments. For Vancouver businesses focused on sustainability and operating cost reduction, these lighting savings compound annually while contributing to LEED certification points and environmental goals.

The downtime factor represents perhaps the most significant hidden cost advantage. Traditional flooring maintenance requires closing sections of facilities, moving inventory or equipment, and disrupting normal operations. Epoxy flooring maintenance requires no downtime—facilities can operate normally during cleaning procedures that take minutes rather than hours or days.

Insurance and liability considerations favor epoxy installations. Many commercial insurance providers offer premium reductions for facilities with slip-resistant, seamless flooring systems that reduce injury risks. The inability of bacteria and contaminants to penetrate epoxy surfaces also reduces liability exposure in healthcare and food service applications.

Facility managers report that epoxy flooring delivers positive return on investment within 3-5 years through reduced maintenance costs alone. When factoring in energy savings, reduced downtime, and insurance benefits, the payback period often shortens to 18-24 months for high-traffic commercial installations.

Design Flexibility: Creating Commercial Spaces That Inspire

Modern commercial epoxy systems have evolved far beyond basic gray or beige coatings. Today’s advanced formulations offer virtually unlimited design possibilities while maintaining the durability and performance characteristics that make epoxy ideal for demanding commercial environments.

Metallic epoxy systems create stunning visual effects that rival expensive natural materials at a fraction of the cost. These systems incorporate metallic pigments that create depth, movement, and unique patterns that make each installation distinctive. Vancouver retail environments, showrooms, and hospitality venues use metallic epoxy to create upscale appearances that would cost 3-4 times more using traditional luxury flooring materials.

Color customization allows businesses to integrate flooring with their branding and aesthetic requirements. Fraser Plus Epoxy can match virtually any color specification, creating cohesive environments that reinforce brand identity. This customization capability is particularly valuable for retail chains and corporate facilities that need consistent aesthetics across multiple locations.

Decorative flake systems combine durability with visual appeal by incorporating colored vinyl flakes that hide minor surface imperfections while adding texture and slip resistance. These systems are particularly popular in automotive facilities, retail environments, and public spaces where both appearance and performance are critical.

Wayfinding and safety marking can be integrated directly into the flooring system during installation. Colored strips, logos, safety zones, and directional indicators become permanent parts of the floor rather than applied graphics that peel, fade, or require replacement. This integration is particularly valuable in warehouses, hospitals, and educational facilities where clear navigation and safety marking are essential.

Texture options range from smooth, high-gloss finishes appropriate for showrooms to aggressive slip-resistant surfaces suitable for wet areas or industrial applications. The texture can be varied within the same installation—creating smooth surfaces for easy cleaning in most areas while providing enhanced traction in specific zones where safety requires additional grip.

Pattern and design possibilities are limited only by imagination and budget. Geometric patterns, simulated materials like marble or granite, and even photographic images can be incorporated into epoxy flooring systems. These advanced decorative techniques allow commercial spaces to achieve unique, memorable aesthetics that differentiate them from competitors while maintaining practical performance benefits.

Implementation Strategy: Planning Your Commercial Epoxy Installation

Successfully implementing commercial epoxy flooring requires careful planning that considers operational requirements, timeline constraints, and long-term maintenance goals. The most successful Vancouver installations involve comprehensive planning that addresses every aspect of the project from initial assessment through long-term care protocols.

Site assessment and preparation form the foundation of successful installations. Professional evaluation includes concrete testing, moisture assessment, contamination identification, and structural evaluation. This assessment phase identifies potential challenges before they become expensive problems during installation, allowing for proper planning and budgeting.

Timeline planning must account for business operations and seasonal factors. Vancouver’s climate provides optimal installation windows during drier months, but advanced coating systems and environmental controls allow year-round installation when necessary. Most commercial projects are scheduled during planned shutdowns, holiday periods, or overnight hours to minimize business disruption.

Product selection should match specific performance requirements rather than simple cost considerations. High-traffic retail environments require different formulations than chemical processing facilities or healthcare settings. Working with experienced contractors like Fraser Plus Epoxy ensures that coating systems are properly matched to actual service conditions and expected lifespan requirements.

Quality control procedures include material testing, environmental monitoring, and post-installation verification. Professional installations include documentation of surface preparation, application conditions, cure times, and final performance testing. This documentation provides warranty protection and establishes baseline conditions for future maintenance planning.

Staff training ensures that facility personnel understand proper cleaning procedures and know how to maintain the investment properly. Most installation contractors provide written maintenance protocols and training for janitorial staff to ensure optimal performance and appearance retention throughout the flooring system’s service life.

Long-term maintenance planning includes periodic inspections, touch-up procedures, and eventual recoating schedules. While high-quality epoxy installations can last decades with minimal maintenance, having established protocols ensures consistent appearance and performance throughout the system’s lifespan.

Fraser Plus Epoxy | Vancouver Epoxy Flooring Expert

Vancouver’s commercial property managers and business owners are discovering that high-performance epoxy flooring isn’t just an alternative to traditional flooring—it’s a superior solution that delivers better performance, lower costs, and greater design flexibility than any conventional option. By choosing advanced epoxy systems and working with experienced installers like Fraser Plus Epoxy, businesses can eliminate the maintenance headaches, appearance problems, and frequent replacement cycles that make traditional flooring so expensive over time. The key is understanding that epoxy flooring is an investment in your facility’s long-term success, providing decades of reliable service while enhancing both the functionality and aesthetic appeal of your commercial space.

Contact Fraser Plus Epoxy today for a free consultation and see how our expert team can customize the perfect solution to fit your facility’s unique needs and budget. Don’t wait—upgrade to a flooring system that saves you time, money, and hassle for years to come!

FAQs

How does Fraser Plus Epoxy ensure the quality of its commercial epoxy flooring installations in Vancouver?

Fraser Plus Epoxy employs advanced surface preparation techniques, moisture mitigation, and adhesion testing to guarantee long-lasting, high-performance epoxy flooring tailored to each facility’s conditions. Their expert installers monitor environmental controls during application for optimal results.What are the slip-resistance options available for epoxy flooring in commercial environments?

Epoxy flooring can be customized with various aggregates or textured finishes to provide tailored slip resistance, ranging from subtle traction for office spaces to aggressive anti-slip surfaces in wet or industrial areas, enhancing workplace safety.Can epoxy flooring be installed year-round in Vancouver despite its wet climate?

Yes, with today’s advanced coating systems and environmental controls, professional installers can manage temperature and humidity to allow epoxy flooring installation throughout the year, minimizing operational downtime for businesses.How do epoxy floors contribute to energy savings in commercial buildings?

Epoxy’s smooth, reflective surface enhances ambient lighting distribution, reducing the need for artificial lighting by 15-25%, which lowers energy consumption and supports sustainability goals.Why should Vancouver businesses choose Fraser Plus Epoxy for their commercial flooring needs?

Fraser Plus Epoxy offers customized, high-quality epoxy flooring solutions that outperform traditional floors in durability and maintenance, backed by industry-leading expertise and excellent customer service across Metro Vancouver.

People Also Ask

What types of commercial facilities benefit most from epoxy flooring?

Epoxy flooring is ideal for high-traffic retail spaces, healthcare facilities, warehouses, schools, and food processing plants due to its durability, seamless hygiene surface, and chemical resistance.How does epoxy flooring compare to ceramic tiles in terms of maintenance?

Unlike ceramic tiles, epoxy floors are seamless with no grout lines, eliminating dirt traps and reducing intensive cleaning requirements, resulting in significantly lower maintenance costs.What causes epoxy floor blistering and how can it be prevented?

Blistering is usually caused by moisture vapor trapped beneath the coating; professional installers use moisture testing and vapor barriers to ensure proper substrate dryness before application.Are epoxy floors environmentally friendly?

Modern epoxy formulations often include low-VOC options and contribute to energy efficiency through enhanced light reflectivity, supporting eco-conscious building certifications.How long does commercial epoxy flooring typically last?

With proper installation and maintenance, epoxy flooring can last 10 to 20 years or more, providing a cost-effective, durable flooring solution for commercial spaces.