Why Epoxy Paint Thickness in MM Matters for Your Floor’s Performance

Epoxy paint thickness in mm is a critical factor determining your floor’s performance and lifespan. Many assume all epoxy coatings are the same, but the reality is more nuanced.

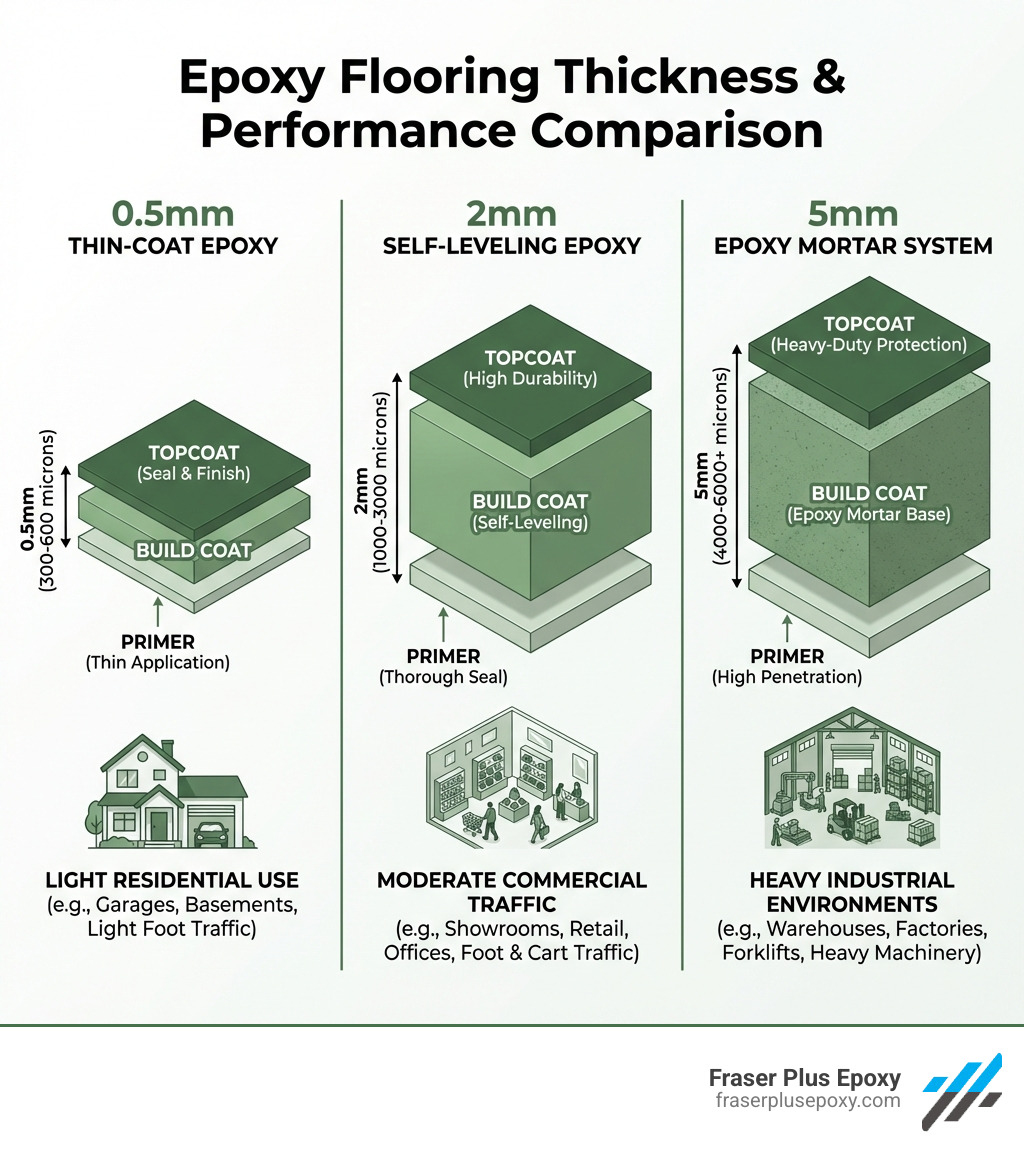

Quick Answer: Common Epoxy Thickness Ranges

- Light Use (Residential Garages, Basements): 0.3mm to 1.0mm

- Moderate Use (Showrooms, Retail, Offices): 2mm to 4mm

- Heavy Use (Warehouses, Factories): 4mm to 10mm+

- Thin-Coat Systems: 0.3mm to 0.6mm (300-600 microns)

- Self-Leveling Systems: 1mm to 3mm

- Epoxy Mortar Systems: 4mm to 6mm or more

Epoxy thickness directly impacts durability, longevity, and performance. A coating that’s too thin won’t hold up, while one that’s too thick can crack, waste money, or fail to cure. The required thickness depends on the floor’s use. A residential garage has different needs than an industrial warehouse with forklifts. The substrate condition, epoxy system type, and number of coats also play a role.

Epoxy thickness is measured in millimeters (mm), microns (µm), or mils. One millimeter equals 1,000 microns or about 40 mils. For example, 300 microns is 0.3mm, and 25 mils is about 0.6mm. These conversions are important when comparing product data sheets or contractor proposals.

I’m Sunny Sidhu, founder of Fraser Plus Epoxy. With over a decade of experience installing epoxy floors across Metro Vancouver, I’ve seen how the right thickness is critical. Proper thickness, preparation, and application are the difference between a floor that lasts 20+ years and one that fails in two.

Recommended Epoxy Thickness Based on Use

Epoxy floor thickness isn’t one-size-fits-all; it depends on the environment and expected use, like traffic and chemical spills. Our goal is a floor that looks great and performs flawlessly for years, whether in a Vancouver home or an industrial facility.

Residential Applications (Garages, Basements)

For residential spaces in Vancouver like garages and basements, the main concerns are cleanliness, dust control, and aesthetics. These areas see light to moderate traffic.

A thickness of 0.3mm to 1.0mm (300-600 microns) is often sufficient for dust-proofing and creating an easy-to-clean surface. We advise caution with DIY water-based epoxy kits from big box stores, as they have a lower solids count and shorter lifespan than professional-grade solid epoxies. For better wear resistance, a 1-2 mm system offers noticeable benefits.

When considering residential epoxy flooring, it’s important to weigh the pros and cons. You can learn more in our guide: What Are the Pros and Cons of Choosing Residential Epoxy Flooring in Vancouver?. For a detailed comparison of garage floor systems, check out our insights on Epoxy Garage Floors Comparison.

Commercial Spaces (Showrooms, Retail, Offices)

Commercial spaces like showrooms, retail stores, and offices face regular foot traffic and light equipment. For these medium-use areas, a greater epoxy paint thickness in mm is appropriate.

We recommend 2mm to 4mm for these spaces. This provides better abrasion resistance for constant foot traffic and regular cleaning. The added thickness also improves longevity and allows for decorative finishes. High-cleanliness areas often use 1.5mm to 2mm for a robust, easy-to-maintain surface.

A well-chosen commercial epoxy floor offers numerous benefits. Explore them in our article: Benefits of a Commercial Epoxy Floor. To add flair, consider decorative metallic epoxy floors: Creative Uses of Decorative Metallic Epoxy Floors in Commercial and Residential Spaces.

Industrial Environments (Warehouses, Factories)

Industrial environments like factories and warehouses demand the most robust epoxy flooring. They endure heavy mechanical wear, chemical abrasion, and constant forklift traffic. For these conditions, a substantial epoxy paint thickness in mm is non-negotiable.

For heavy-use flooring, we recommend 4mm to 10mm or more. Workshops with large machinery often need 3mm to 5mm. For extreme conditions in industries like metal construction or heavy chemical processing, floors can exceed 5mm and even reach 1 cm. These floors (over 6mm thick) are designed to absorb shocks and protect the concrete substrate.

Industrial flooring is about engineering a solution for the harshest conditions. Learn more about our specialized solutions on our Industrial Flooring page.

How Epoxy System Type Dictates Thickness

The epoxy system type is crucial for determining the final epoxy paint thickness in mm. Different systems are formulated for specific performance levels, application methods, and finishes. Understanding these is key to selecting the right solution for your Vancouver property.

| System Type | Typical Thickness (mm) | Key Use Cases | Durability Level | Application Method |

|---|---|---|---|---|

| Thin-Coat Epoxy | 0.3 – 0.6 | Residential garages, basements, light commercial offices | Light | Roller |

| Self-Leveling Epoxy | 1.5 – 3.0 | Showrooms, commercial kitchens, clean rooms, light industry | Moderate to High | Notched squeegee, trowel |

| Epoxy Mortar/Quartz | 4.0 – 10.0+ | Heavy industrial, manufacturing, high impact/abrasion | Very High | Trowel |

Thin-Coat Epoxy Systems

Thin-coat epoxy is the most economical option for light-duty use. These systems consist of a primer and one or two paint coats, for a total thickness of 0.3mm to 0.6mm (300-600 microns). These roller-applied coatings are excellent for dust-proofing, improving appearance, and providing basic protection. They suit lightly worn floors like offices or storage areas. For more traffic or impact, a thicker system is recommended.

Self-Leveling Epoxy Systems

Self-leveling epoxy is popular for its smooth, seamless finish. It flows evenly to create a flat surface, ideal for high-standard clean places. These systems are typically 2mm to 3mm thick, though the range can be 1.5mm to 10mm depending on project needs. We apply these with a notched squeegee to control thickness and ensure a smooth finish. For a technical example, see the Sikafloor® MultiDur ES-31 data sheet, which has a nominal thickness of 2mm to 3mm: View a technical data sheet for a self-leveling system.

Epoxy Mortar and Quartz-Filled Systems

For maximum durability and resistance to impact and chemicals, we use epoxy mortar and quartz-filled systems. These are the strongest systems, made with 100% solids epoxy and graded aggregates. These trowel-applied systems achieve a substantial epoxy paint thickness in mm, from 4mm to 6mm or even over 10mm for demanding projects. Aggregates like quartz sand significantly impact thickness and durability.

Key benefits of adding aggregates:

- Improved Strength: Aggregates increase compressive strength and impact resistance.

- Improved Abrasion Resistance: Hard particles resist scratching and wear in high-traffic areas.

- Increased Thickness: Aggregates build significant thickness in fewer layers for heavy-duty applications.

- Anti-Slip Properties: Broadcasting aggregates creates a textured, slip-resistant finish. Anti-slip systems typically range from 1mm to 4mm. You can watch a video here to see how anti-slip quartz floors are made.

Choosing the right epoxy and using high-quality materials makes all the difference. Learn more in our article: Why Using High-Quality Materials Makes All the Difference in Vancouver Epoxy Flooring.

The Foundation: How Substrate and Preparation Impact Epoxy Paint Thickness in mm

The concrete slab’s condition is the foundation for your epoxy floor. We carefully assess and prepare it, as this directly influences adhesion, longevity, and the required epoxy paint thickness in mm.

Assessing the Concrete Substrate

Just as you wouldn’t build on a shaky foundation, the same applies to epoxy flooring. We assess several factors:

- Porosity: Highly absorbent concrete may need a thicker primer or an extra layer to seal the surface.

- Cracks and Spalling: We repair minor cracks and spalling. Heavily damaged substrates may need a thicker mortar system to fill voids and add structural integrity, a common issue in Vancouver’s climate. For expert repair techniques, see our guide: Vancouver Epoxy Floor Repair Techniques, Tools, and Best Practices.

- Moisture Content: Excessive moisture causes adhesion failure. We test for moisture and apply mitigation solutions if needed, which can affect the system layers.

- Uneven Surfaces: Uneven slabs require more material to level. Self-leveling epoxies help, but extreme unevenness means a greater final thickness.

A damaged or uneven substrate requires a thicker system because the epoxy must also fill, level, and reinforce. This demands more material, increasing the epoxy paint thickness in mm.

Surface Preparation and its link to epoxy paint thickness in mm

Proper surface preparation is the bedrock of a successful epoxy floor. Thicker coats require more aggressive preparation for proper anchoring to the substrate. We follow strict protocols for optimal adhesion, as detailed in The Science of Epoxy Flooring Adhesion: How It Bonds to Different Substrates.

Our primary methods include:

- Diamond Grinding: This removes contaminants and old coatings, creating a clean, rough surface for the epoxy to bond with.

- Shot Blasting: For large industrial areas, this method uses high-speed abrasive media to create an ideal surface profile.

- Creating a Surface Profile (CSP): Grinding and shot blasting create a specific CSP (Concrete Surface Profile). Most epoxies need CSP-2 to CSP-4, while thicker systems may need CSP-5 or higher for a better mechanical grip.

- Crack Filling: We route and fill all cracks with specialized epoxy fillers before coating. This creates a stable base and prevents cracks from showing through.

Why is aggressive prep needed for thicker coats? A rougher surface creates a stronger mechanical bond. A heavy-duty system needs an incredibly strong bond to prevent delamination, which can happen even with thick epoxy if prep is poor. After grinding, ensuring a Clean Concrete Floor After Grinding is paramount.

Building the System: The Role of Each Coat

A high-performance epoxy floor is a multi-coat system. Each coat has a distinct purpose in achieving the desired epoxy paint thickness in mm and performance. Our industrial systems often use three layers over the prepared concrete, a cornerstone of our Expert Strategies for Reliable Epoxy Floor Installation in Vancouver That Stands the Test of Time.

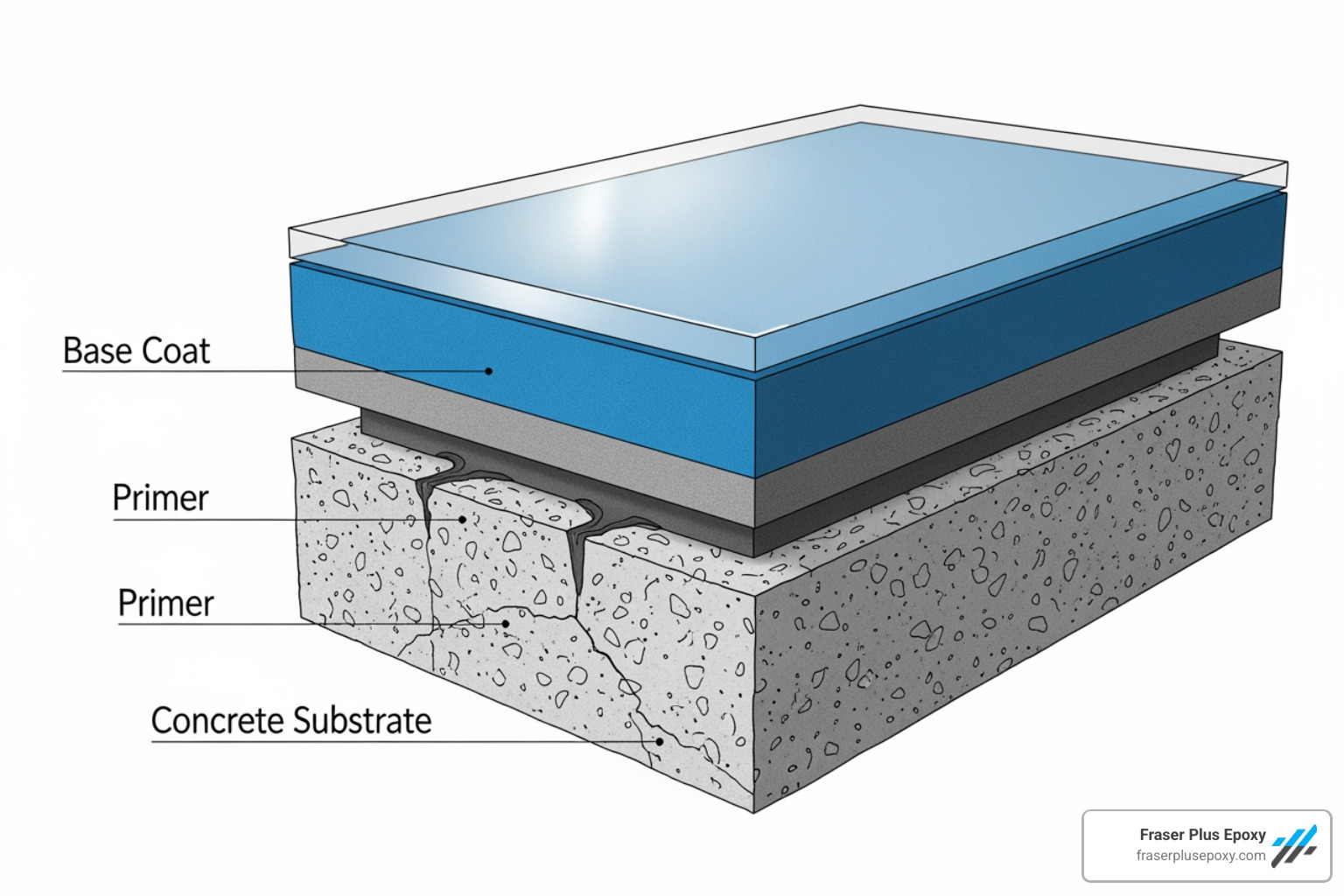

The Primer Coat: Sealing the Foundation

The primer is the first and most crucial layer, acting as the ‘glue’ that bonds the system to the concrete. It penetrates pores for a strong bond, ensures adhesion for subsequent layers, and prevents outgassing (bubbles). A primer coat adds about 0.15mm to 0.3mm to the total thickness. Without a proper primer, even the thickest system will fail.

The Build Coat(s): Creating the desired epoxy paint thickness in mm

The build coat(s) provide the bulk of the epoxy paint thickness in mm and are engineered for strength. This layer absorbs impacts, withstands heavy loads, and provides structural integrity. Multiple build coats can be applied to achieve the target thickness. For added durability or decoration, aggregates or flakes are broadcast into the wet build coat. Most garage floors require two to three coats, with the second coat serving as the primary build layer.

The Topcoat: The Protective Shield

The topcoat is the final protective shield. It’s the visible surface, engineered for specific performance characteristics:

- Wear Layer: It’s formulated to withstand daily wear, abrasion, and traffic.

- UV Resistance: A UV-stable topcoat is crucial for floors exposed to sunlight to prevent yellowing.

- Chemical Resistance: It provides resistance to chemicals, oils, and solvents, which is vital in industrial settings. Learn more in our guide on Top Application Techniques to Maximize Chemical Resistance Floor Coatings.

- Determines Finish: The topcoat defines the aesthetic finish (e.g., gloss, satin).

- Anti-Slip Properties: For safety, anti-slip additives can be added, or the topcoat can encapsulate aggregates to create a textured, slip-resistant surface.

A self-leveling floor’s topcoat is often 0.7mm to 1mm, for a total thickness of 2.5mm to 3mm. Specialized floors like anti-static or colored sand systems can reach 3mm to 5mm, with the topcoat being key for protection and aesthetics.

Frequently Asked Questions about Epoxy Thickness

Here are answers to common questions about epoxy paint thickness in mm, based on our decade of experience in Vancouver.

Can an epoxy coating be too thick?

Yes, an epoxy coating can be too thick. ‘More is better’ doesn’t always apply. Excessively thick coatings can lead to curing problems, brittleness, and cracking. It also wastes money without adding proportional performance benefits. Following manufacturer specifications for thickness is crucial, and our teams are trained to apply epoxy within these parameters for optimal performance.

How is epoxy thickness measured?

Accurately measuring epoxy thickness is crucial for quality control. We use several methods:

- Wet Film Thickness (WFT) Gauges: These comb-like tools are used on wet epoxy for an immediate thickness check during application.

- Dry Film Thickness (DFT) Gauges: After curing, these electronic devices measure the dry coating’s thickness without damage. It’s the most common verification method.

- Calculation: Theoretical thickness can be calculated from the product’s solids content and coverage rate, which is useful for planning. For example, a 100% solids product covering 160 sq ft/gallon yields about 10 mils (0.25mm) per coat.

- Destructive Testing: In some cases, a small core sample is taken and examined under a microscope for precise measurements.

Does a thicker epoxy floor last longer?

Generally, yes, a thicker epoxy floor lasts longer by resisting wear and impact. However, this depends on having the correct thickness for the application.

- Wear and Impact Resistance: A thicker layer provides more material to absorb impacts and resist abrasion. A 5mm mortar floor will withstand more abuse than a 0.5mm thin-coat system. Common thicknesses range from 0.3mm to 5mm, but can reach 1 cm in extreme environments.

- Correct Thickness is Key: The thickness must match the intended use. A 2mm floor is fine for a showroom but not a factory. A 10mm system in a basement is overkill and not cost-effective.

- Poor Installation Undermines Thickness: A poorly installed thick floor will fail faster than a well-installed thin one. Inadequate preparation, incorrect mixing, or improper curing can cause peeling or chipping, shortening the floor’s lifespan regardless of thickness. Learn more about preventing these issues in our guide: What to Do When Your Epoxy Floor Peels or Chips: Causes and Solutions for Vancouver Homeowners.

In short, while thickness correlates with longevity, it must be the right thickness, applied correctly, for the specific environment.

Achieve the Perfect Epoxy Floor Thickness in Vancouver

Understanding epoxy paint thickness in mm is more than picking a number; it’s a critical decision impacting your floor’s performance, longevity, and value. Across Metro Vancouver, from industrial zones in Surrey to residential garages, the right thickness is paramount.

Here are our key takeaways:

- Thickness is Application-Specific: The ideal thickness depends on its intended use, traffic, and exposure to chemicals or impacts.

- Use Dictates Thickness: Residential use may only need 0.3mm-1.0mm, while heavy industry can require 4mm-10mm+. Different systems (thin-coat, self-leveling, mortar) yield different thicknesses for specific environments.

- Preparation is Key: The substrate’s condition and preparation are foundational. A poorly prepared surface may require a thicker system or risk premature failure.

- Multi-Coat Systems Perform Best: A well-engineered floor includes a primer, build coat(s), and a topcoat. Each layer is vital for achieving the desired thickness, adhesion, and strength.

At Fraser Plus Epoxy, we engineer flooring solutions. With over a decade of experience in Metro Vancouver, we understand local demands. We assess your needs, prepare your substrate perfectly, and apply the ideal epoxy system at the correct thickness for a beautiful, durable, and long-lasting floor.

Don’t leave the longevity and performance of your floor to chance. For expert consultation on your next project, explore our epoxy flooring services.