Why Diamond Grinding is Essential for Concrete Surface Preparation

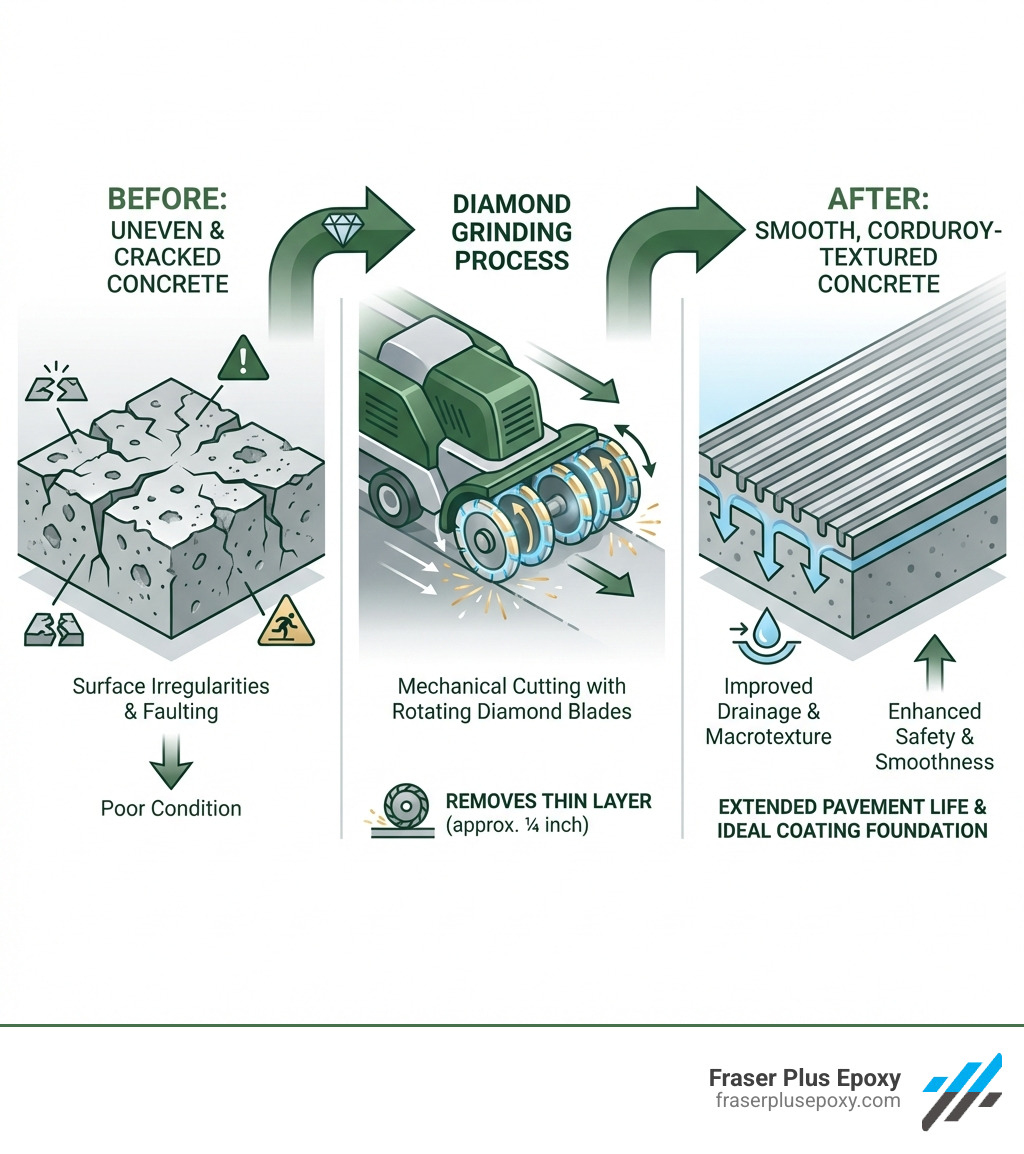

What is diamond grinding? Diamond grinding is a concrete pavement preservation and restoration technique that removes a thin layer of hardened concrete (typically ¼ inch) using closely spaced diamond saw blades. This cutting process creates a smooth, level surface with a distinctive longitudinal texture that improves safety, extends pavement life, and provides an ideal foundation for protective coatings.

Key Facts About Diamond Grinding:

- Process: Mechanical cutting (not impact) using industrial diamond blades mounted on a rotating head

- Material Removal: Removes 3/16 to 1/4 inch (5-7 mm) of surface concrete

- Result: Creates a corduroy-like textured surface that is smooth yet slip-resistant

- Applications: Highways, commercial floors, industrial facilities, residential garages

- Benefits: Improved smoothness, improved safety, reduced noise, extended surface life

- Cost: Typically $2.00-$8.00 per square meter, often half the cost of overlays

- Longevity: Average service life of 16-17 years, with surfaces re-grindable 2-3 times

Concrete surfaces deteriorate over time. Repetitive stress and strain from traffic, weather, and use create potholes, cracks, and rough patches. These imperfections aren’t just unsightly—they’re dangerous and costly.

Diamond grinding addresses these problems by removing surface irregularities and creating a uniform texture. The process restores smoothness, improves traction, reduces noise, and extends the life of concrete pavements and floors by many years. It’s cost-effective, often costing about half as much as asphalt overlays, and it doesn’t raise surface elevation or affect overhead clearances.

The technique has been proven since the 1960s. A section of Interstate 10 in California was first ground in 1965, then again in 1984 and 1997, and it’s still carrying heavy traffic more than 60 years later.

For commercial and industrial facilities, diamond grinding serves as critical surface preparation before applying protective coatings like epoxy. The textured profile created by grinding provides excellent mechanical bonding for high-performance floor systems.

As Sunny Sidhu, founder of Fraser Plus Epoxy, I’ve seen how proper concrete preparation—including what is diamond grinding techniques—makes the difference between a coating that lasts years versus one that fails prematurely. Over the past decade working on commercial and industrial projects across Metro Vancouver, I’ve relied on diamond grinding to create the ideal surface profile for durable, long-lasting epoxy floor systems.

The Core Process: What is Diamond Grinding?

When we talk about achieving truly superior finishes for concrete, whether it’s for a busy warehouse floor in Surrey or a sleek showroom in Vancouver, understanding what is diamond grinding is fundamental. At its heart, diamond grinding is a precise and powerful method of concrete surface preparation.

It’s a process that carefully corrects a variety of surface imperfections on concrete pavements and floors. Unlike other methods that might chip or impact the surface, diamond grinding is a cutting process. This distinction is crucial; it means we’re not just banging away at the concrete but carefully shaving off a thin, uniform layer. Typically, this involves removing about 3/16 to 1/4 inch (5 to 7 mm) of the surface. This removal creates a perfectly level, textured surface, ready for its next life.

This precision sets it apart from other common surface preparation techniques. For instance, shot blasting uses small steel abrasive shot propelled at the surface to create a profile, and scarifying uses rotating flails to chip away at the concrete. While these have their places, diamond grinding offers a smoother, more controlled removal, which is often essential for high-performance coatings or polished finishes. The result is a consistent surface profile, free from major peaks and valleys, which is ideal for adhesion and aesthetics.

How Does the Diamond Grinding Process Work?

So, how does this magic happen? The process relies on specialized heavy-duty equipment. Imagine a large machine with a wide cutting head, typically 3 to 4 feet across. This head is equipped with hundreds of closely spaced diamond saw blades. These aren’t just any diamonds; they’re industrial-grade diamonds, often embedded in a metallurgical powder matrix, chosen for their incredible hardness and abrasive properties. The blades are gang-mounted on a rotating shaft, and the spacing between them, controlled by metal spacers, dictates the texture we achieve.

As the machine moves, these blades rotate and grind down the concrete surface. Water is continuously applied during the process, serving a dual purpose: it cools the diamond blades, extending their life, and it helps to suppress dust, creating a safer and cleaner working environment. The grinding action produces a watery concrete paste, known as slurry. This slurry is immediately collected by an on-board vacuum and disposal system, preventing it from spreading and ensuring a clean work site. This is particularly important for environmental compliance in places like Metro Vancouver, where proper waste management is key.

The outcome is a distinctive “corduroy-like” texture—a series of parallel longitudinal grooves and flat lands. This texture is not only aesthetically pleasing but also engineered for performance, providing optimal grip and drainage. For those interested in the full scope of preparing a surface for a new coating, we have more info about the epoxy installation process that digs into these crucial first steps.

The Historical Origins of the Technique

It might seem like a modern marvel, but the origins of diamond grinding stretch back further than many realize. The industry can trace its roots to the late 1940s, evolving from a simple concept: a single diamond blade mounted on a concrete saw. Fast forward to the 1960s, and we see the first significant applications of what we now recognize as modern diamond grinding.

This pioneering work, particularly on pavements like Interstate 10 in California, demonstrated the immense potential of the technique. Since then, the evolution has been continuous. Advances in equipment, coupled with improvements in synthetic diamond technology, have transformed it into a highly efficient and cost-effective solution. What began as a niche application has grown into a multimillion-dollar industry practiced worldwide, including here in Canada. Organizations like the International Grooving & Grinding Association (IGGA) and the American Concrete Pavement Association (ACPA) have played a significant role in advancing best practices, sharing knowledge, and ensuring the continued development and adoption of this valuable technology.

The Transformative Benefits of a Diamond-Ground Surface

The moment you step onto, or drive over, a surface that has undergone what is diamond grinding, the difference is palpable. It’s not just about making something look new; it’s about fundamentally improving its quality and performance.

The primary goal is always improved surface quality. This means restoring smoothness by eliminating irregularities like faulting at joints and cracks, correcting unevenness from construction, and dealing with the general wear and tear that makes a surface rough and uncomfortable. By creating a uniformly smooth surface, we significantly reduce what engineers call “dynamic loading.” Imagine a heavy truck hitting a bump; it bounces, and that impact delivers a much greater stress to the pavement than if it were rolling smoothly. Diamond grinding removes these bumps, leading to a reduction in this dynamic loading, which in turn extends the life of the concrete structure itself. It’s like giving your floor a fresh, even canvas to work with.

Improved Safety and Performance

Beyond comfort, the safety benefits of diamond grinding are profound, especially in a region like Metro Vancouver, which experiences its share of wet weather. The corduroy-like texture created by the process dramatically increases the surface’s macrotexture. Think of macrotexture as the larger-scale roughness that allows water to escape from under a tire.

This improved macrotexture translates directly into improved slip resistance and reduced potential for standing water. The longitudinal grooves act as efficient channels for water displacement, moving rain and melting snow away from the tire-pavement interface. This significantly reduces the risk of hydroplaning, a terrifying experience for any driver, and improves overall traction and stability. For industrial and commercial floors, this means a safer working environment, reducing slips and falls, and improving the operational safety of forklifts and other equipment. If you’re looking for surfaces that can stand up to spills and provide superior grip, you might also be interested in more on chemical resistant flooring.

A Quieter and More Sustainable Solution

One of the less obvious, but increasingly important, benefits of diamond grinding is its contribution to a quieter environment. Studies have shown that diamond-ground surfaces can lead to a significant noise reduction, sometimes up to 5 dB(A) in industrial and commercial settings. This is because the longitudinal texture minimizes the tire-road contact area and can even trap air, dampening tire-pavement noise. For facilities and communities adjacent to busy roads, this can make a noticeable difference in quality of life.

From an environmental perspective, diamond grinding is a truly sustainable practice. Instead of tearing up and replacing entire concrete sections, which is resource-intensive and generates a lot of waste, we’re rehabilitating the existing structure. We’re extending the life of the concrete that’s already there, using a minimal amount of material removal to achieve maximum benefit. This approach reduces the demand for new raw materials, minimizes landfill waste, and lowers the carbon footprint associated with construction. It’s a smart way to make our infrastructure last longer and contribute to greener building practices. To learn more about how flooring solutions can align with environmental goals, we invite you to learn about sustainable flooring standards.

Longevity, Cost, and Comparison to Other Methods

When we invest in our infrastructure or our commercial spaces, we want solutions that deliver long-term value. Diamond grinding stands out as a method that truly pays dividends over time.

It’s about more than just a quick fix; it’s about a strategic investment that ensures durability and performance for years to come.

Expected Service Life and Re-Grinding Potential

One of the most compelling aspects of diamond grinding is the remarkable extension it offers to a concrete surface’s lifespan. While the average lifespan of diamond-ground pavement varies slightly depending on the specific study and conditions, reports consistently show impressive longevity. Caltrans, for example, reports an average life of a diamond-ground surface between 16 and 17 years. Other studies indicate that 90 percent of diamond-ground pavements last at least 9.5 years, and 50 percent last at least 13.5 years. Some sources even suggest a service life of approximately 30 years for highway pavements.

What’s truly remarkable is the potential for re-grinding. A typical concrete pavement, whether it’s a road or a heavy-duty industrial floor, can often be ground up to three times without significantly compromising its structural integrity or fatigue life. This means that an initial investment in diamond grinding can be renewed, extending the life of the concrete for decades. For instance, a section of Interstate 10 in California, originally ground in 1965, was re-ground in 1984 and again in 1997, continuing to serve heavy traffic for over 60 years. This capability makes it an incredibly sustainable and cost-effective long-term solution. You can dig deeper into this topic with comprehensive research on the Longevity and Performance of Diamond-Ground Surfaces.

What is the cost-effectiveness of diamond grinding?

When considering rehabilitation or surface preparation options, cost is always a major factor. The cost-effectiveness of diamond grinding is one of its strongest selling points. On average, diamond grinding costs between $2.00 and $8.00 per square meter ($1.70 and $6.70 per square yard). While this can fluctuate based on factors like the hardness of the aggregate (very hard river gravel might push costs up to $12/m²), it remains highly competitive.

In most cases, the cost of diamond grinding is only about half the cost of bituminous overlays for pavements. For floors, it’s often significantly less expensive than full demolition and replacement. Beyond the initial cost savings, it avoids many problems associated with overlays, such as reducing overhead clearances or requiring tapers at intersections. This means less disruption and lower associated costs. We understand that budget is always a consideration for our clients in Metro Vancouver, and we’re committed to providing solutions that offer exceptional value. For a broader perspective on renovation costs, you can explore understanding flooring installation costs.

Diamond Grinding vs. Other Concrete Surface Prep Methods

To truly appreciate the value of diamond grinding, it helps to compare it with other common concrete surface preparation methods we use, such as shot blasting and scarifying. Each has its place, but diamond grinding often excels for specific outcomes.

| Feature | Diamond Grinding | Shot Blasting | Scarifying |

|---|---|---|---|

| Service Life | Extends concrete life by decades (re-grindable) | Prepares for coatings, life tied to coating | Prepares for coatings, life tied to coating |

| Initial Cost | Moderate to High (due to precision and equipment) | Low to Moderate | Low to Moderate |

| Noise Levels | Moderate (during operation, but results in quieter road/floor) | High (during operation) | High (during operation) |

| Sustainability | High (preserves existing concrete, reduces waste) | Moderate (preps existing concrete, less material removal) | Moderate (preps existing concrete, more aggressive) |

| Application Time | Moderate to High (multi-pass process) | Fast | Fast |

| Impact on Surface Profile | Creates smooth, level, corduroy-like texture (CSP 2-3) | Etches surface, creates uniform roughness (CSP 3-5) | Aggressively removes material, rough texture (CSP 4-7) |

As you can see, what is diamond grinding offers a unique blend of precision, longevity, and versatility, making it an excellent choice for a wide range of projects where a superior, long-lasting finish is the goal.

Project Suitability: Is Diamond Grinding the Right Choice?

Selecting the right concrete treatment is crucial for any project. While diamond grinding offers numerous benefits, it’s not a one-size-fits-all solution. At Fraser Plus Epoxy, we carefully evaluate each project to ensure that diamond grinding is the most appropriate and effective method.

Key considerations for project selection include the current condition of the concrete, its age, the expected traffic or use, and any previous rehabilitation history. We look for signs of surface irregularities like faulting, slab warping, or construction roughness. There’s what we call a “window of opportunity” – a point in the concrete’s life cycle where diamond grinding is most cost-effective and will yield the best results. If the concrete is too far gone with severe structural issues, other methods might be more suitable. Assessing the depth of sound concrete is also critical, as we need enough material to remove the imperfections without compromising the slab’s structural integrity.

Typical Applications and Use Cases

The versatility of diamond grinding means it’s applicable in a wide array of situations, from major highways to local commercial floors throughout Metro Vancouver. Here are some of its typical applications:

- Correcting unevenness: This is one of the most common uses, addressing issues like faulting at joints and cracks where one slab might be higher than another, or general construction roughness that leaves a bumpy surface.

- Leveling slab warping and curling: Concrete slabs can warp or curl due to temperature changes or moisture imbalances, leading to an uneven surface. Diamond grinding effectively levels these distortions.

- Fixing construction roughness: Sometimes, new concrete pours aren’t perfectly smooth. Diamond grinding can correct these initial imperfections, creating a high-quality finish from the start.

- Removing surface imperfections: This includes polished aggregates that have lost their grip, rutting caused by studded tires (less common in BC now, but historically relevant), or other surface defects that compromise safety or aesthetics.

- Improving surface quality for epoxy flooring, industrial floors, and commercial spaces: For us, this is paramount. Diamond grinding creates the ideal Concrete Surface Profile (CSP) – typically CSP 2-3 – that allows epoxy coatings to bond mechanically and optimally, ensuring a durable and long-lasting finish for our clients in Burnaby, Richmond, or Langley.

- Restoring transverse slope: This ensures proper water drainage across the surface, preventing ponding and improving safety.

What is diamond grinding not suitable for?

While powerful, diamond grinding does have its limitations. It’s important to understand these to ensure we recommend the best solution for your concrete.

- Not a solution for severe structural damage: If a concrete slab is severely cracked, shattered, or has widespread deep cracking, diamond grinding won’t fix the underlying structural problem. It addresses surface issues, not foundational failures.

- Unsuitable for material durability problems: Issues like D-cracking (a form of freeze-thaw damage where aggregate expands), alkali-aggregate reactivity, or other inherent material durability problems cannot be solved by grinding. While grinding can prevent some freeze-thaw issues by keeping surfaces dry, it won’t cure a material that’s inherently failing.

- Not for surfaces with incompatible base materials: Diamond grinding requires a concrete base. It cannot be used on asphalt-based surfaces, as the cutting mechanism and desired outcome are fundamentally different.

Diamond grinding is a precision tool for surface rehabilitation and preparation. If the problem lies deeper, a more comprehensive structural repair might be necessary before any surface treatment.

Frequently Asked Questions about Diamond Grinding

We often get asked specific questions about what is diamond grinding, especially from clients considering it for their commercial or industrial properties in Metro Vancouver. Here are some of the most common ones:

How much material does diamond grinding remove?

Typically, diamond grinding removes a thin layer of concrete, ranging from about 3/16 to 1/4 inch (5 to 7 mm). This precise removal is enough to eliminate surface imperfections and restore smoothness without significantly compromising the structural integrity or fatigue life of the concrete slab. The depth of removal is carefully controlled to achieve the desired surface profile while preserving as much of the original material as possible.

Can diamond grinding be performed on residential driveways or garage floors?

Absolutely! While often associated with large-scale highway projects, diamond grinding is also incredibly effective for residential applications. We use smaller, more maneuverable grinding equipment to prepare residential concrete surfaces, such as driveways, patios, and especially garage floors. This process is key for leveling uneven areas, removing old coatings or contaminants, and creating the perfect profile for new decorative finishes or protective coatings. It’s a critical step in achieving a professional garage epoxy floor finish that is both durable and aesthetically pleasing for homes in areas like Coquitlam or West Vancouver.

Does diamond grinding fix deep cracks in the concrete?

No, diamond grinding primarily addresses surface-level imperfections. It’s excellent for removing minor cracks, spalling, and surface roughness. However, for deep structural cracks that extend significantly into the concrete slab, diamond grinding is not the solution. These types of cracks require more intensive repair methods, such as epoxy injection, routing and sealing, or full-depth patching, which should be performed before any grinding takes place to ensure the overall integrity of the concrete. We always assess the extent of cracking to recommend the most appropriate repair strategy.

Conclusion: Achieving a Superior Surface with Expert Preparation

We’ve explored what is diamond grinding, delving into its precise process, historical roots, and the multitude of benefits it offers. From extending the lifespan of concrete surfaces by decades and enhancing safety through improved traction and drainage, to reducing noise pollution and proving remarkably cost-effective, diamond grinding is a truly transformative technique. It’s a testament to how intelligent engineering can make our infrastructure and our commercial spaces more durable, safer, and more sustainable.

The critical role of surface preparation cannot be overstated for any high-performance floor or concrete finish. Just as a painter prepares their canvas, we believe that the foundation for a flawless, long-lasting epoxy floor or a beautifully polished concrete surface lies in meticulous preparation. Diamond grinding ensures that foundation is as perfect as possible, providing the optimal mechanical bond for subsequent coatings and finishes.

At Fraser Plus Epoxy, with our decade of experience serving businesses and homeowners across Vancouver and Metro Vancouver, we stand by the power of expert concrete preparation. Our commitment to quality means we leverage advanced techniques like diamond grinding to ensure every epoxy floor we install, and every polished concrete surface we create, meets the highest standards of durability and aesthetic appeal.

Ready to transform your concrete surface into a smooth, safe, and long-lasting asset? Explore our premium epoxy flooring solutions and find how our expertise in diamond grinding and other preparation techniques can bring your vision to life.