Why Epoxy Flooring Self Leveling Transforms Problem Floors

Epoxy flooring self leveling is a specialized coating system designed to create perfectly flat, seamless surfaces over damaged, uneven, or cracked concrete. Here’s what you need to know:

Quick Answer: Applying Self-Leveling Epoxy

- Prepare the concrete – grind to CSP 2-3, clean thoroughly, repair cracks, test for moisture

- Apply primer – use moisture-appropriate primer, allow to cure 30 minutes to 24 hours

- Mix and pour – combine resin and hardener, pour in ribbons within 30-60 minute pot life

- Spread and level – use notched squeegee, back-roll with spiked roller, wear spiked shoes

- Allow to cure – 24 hours for light traffic, 7 days for full cure

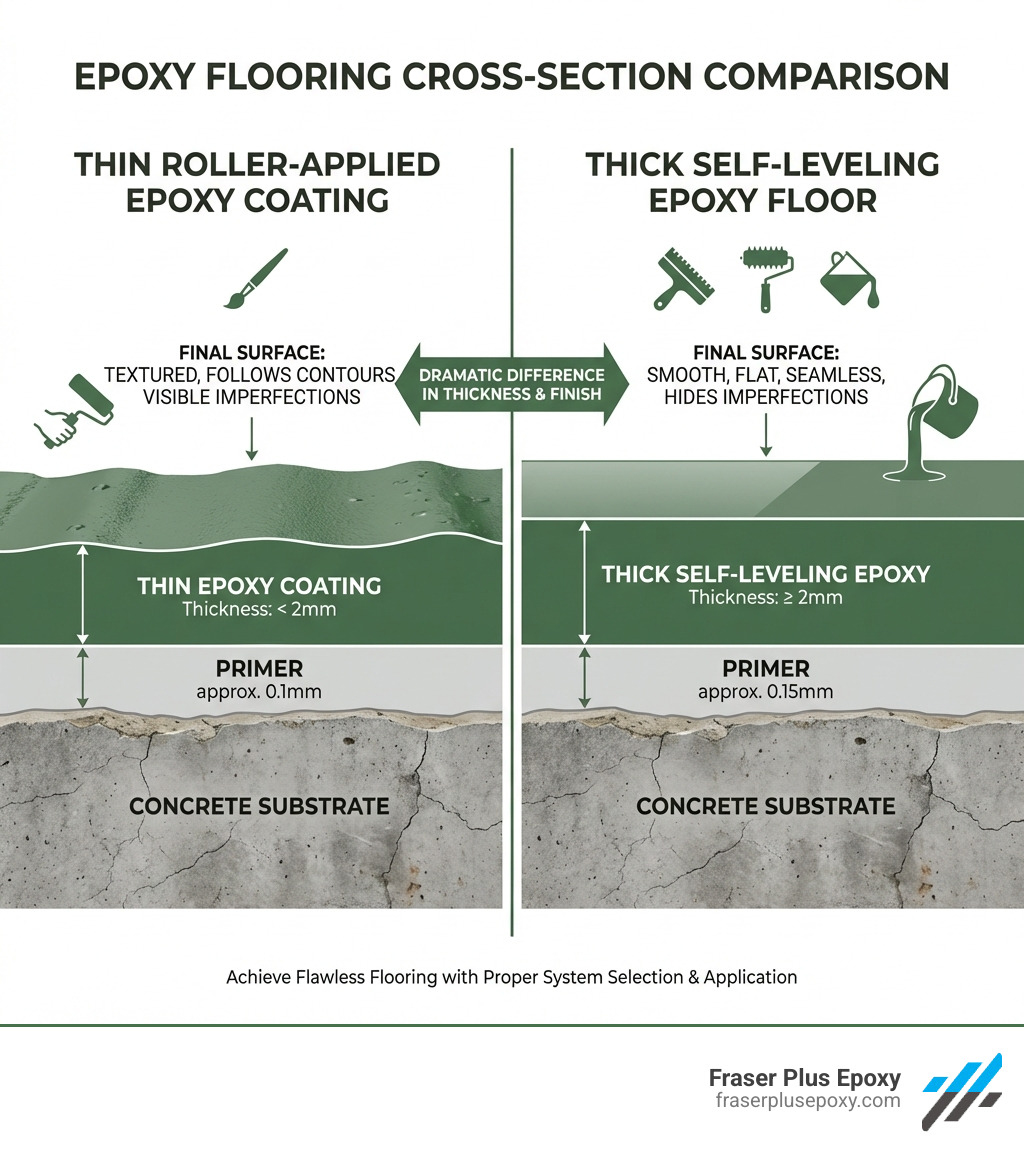

Key Differences from Standard Epoxy:

- Minimum 2mm thick (standard coatings are less than 2mm)

- Self-levels through gravity and reduced surface tension

- Uses 100% solids with no VOCs

- Costs 4-5 times more but lasts 10-20 years

- Hides concrete imperfections that thin coatings cannot

Uneven floors create real problems. Equipment doesn’t sit level, liquids pool in low spots, and the whole space looks unprofessional. Regular epoxy behaves like honey—it stays where you spread it and follows existing contours. Self-leveling epoxy flows like milk, finding its own level through gravity to cure into a perfectly flat surface.

The technology relies on specialized leveling agents that reduce viscosity and surface tension. Most systems give you 30-60 minutes of working time before curing advances too far. This short window demands proper planning and execution—there’s no room for error when you’re pouring material that costs significantly more than roller-applied alternatives.

I’m Sunny Sidhu, founder of Fraser Plus Epoxy, and I’ve installed hundreds of commercial and residential epoxy flooring self leveling systems across Metro Vancouver’s warehouses, manufacturing facilities, showrooms, and garage spaces. My background in large-scale commercial installations has taught me that proper substrate preparation and precise application technique make the difference between a floor that lasts two decades and one that fails within months.

Understanding Self-Leveling Epoxy

When we talk about epoxy flooring self leveling, we’re discussing a high-performance flooring solution that stands apart from standard epoxy coatings. It’s designed to create a remarkably smooth, durable, and aesthetically pleasing surface, even over imperfect concrete.

At its core, self-leveling epoxy is a two-component system, typically consisting of a resin (Part A) and a hardener (Part B). What makes it “self-leveling” are specialized chemical properties, including carefully engineered leveling agents. These agents reduce the surface tension and viscosity of the mixed material, allowing it to flow out smoothly and find its own level due. Think of it like pouring milk onto a surface – it naturally spreads and seeks the lowest points until it’s flat. In contrast, a standard epoxy coating, which is much thinner, behaves more like honey, retaining brush or roller marks and following the existing contours of the floor.

A key characteristic of high-quality epoxy flooring self leveling systems is that they tend to be 100% solids. This means that once cured, there’s no solvent evaporation, resulting in a thick, dense, and incredibly durable floor. This also translates to very low or even no VOCs (Volatile Organic Compounds), making it a more environmentally friendly option and safer for indoor applications in places like homes and businesses across Burnaby, Coquitlam, and Langley.

The benefits of using self-leveling epoxy flooring are extensive:

- Durability and Wear Resistance: Because self-leveling epoxy floors are applied at a minimum thickness of 2mm (often thicker, up to 3/8 inch or more), they offer superior long-term resistance to wear and tear compared to thinner coatings (which are less than 2mm thick). This makes them ideal for high-traffic areas.

- Seamless Surface: The material flows to create a truly seamless floor, eliminating grout lines or seams where dirt, bacteria, and moisture can accumulate. This is a huge advantage for hygiene and cleaning.

- Easy Cleaning: The smooth, non-porous surface is incredibly easy to clean and maintain. Daily dust mopping or light washing with mild detergents is usually all that’s required.

- Hiding Imperfections: One of the standout features is its ability to smooth over minor dents, divots, and imperfections in the underlying concrete. While major cracks and damage still require repair, the self-leveling properties can transform an old, worn-out concrete slab into a pristine surface.

- Aesthetic Options: Beyond functionality, self-leveling epoxy offers fantastic aesthetic versatility. We can achieve a high-gloss, mirror-like finish that truly shines. It’s available in a wide range of colors, and for a truly unique look, metallic pigments can be added to create stunning, three-dimensional effects. We can also incorporate decorative flakes or quartz aggregates for added visual appeal and texture.

- Specialty Formulations: For specific needs, there are specialty formulations:

- Fast-Cure Systems: These are perfect for projects that require a quick turnaround, setting in as little as 2-4 hours.

- Electrically Conductive Epoxy: Used in environments where static discharge is a risk (e.g., electronics manufacturing, areas with flammable materials), these formulations contain conductive materials to dissipate static electricity.

- Antimicrobial Products: Essential for hygiene-critical environments like food processing plants, pharmaceutical facilities, and healthcare settings, these products inhibit bacterial growth.

To give you a clearer picture, here’s a comparison of self-leveling epoxy versus roller-applied epoxy:

| Feature | Self-Leveling Epoxy | Roller-Applied Epoxy |

|---|---|---|

| Thickness | Minimum 2mm (typically 2-3mm or more), up to 3/8 inch for high-build systems | Less than 2mm (typically around 400 microns) |

| Cost | Product consumption cost is 4-5 times higher (requires ~2kg/m2 + sand) | Much lower product consumption cost (requires ~600 gr/m2 for primer + 2 coats) |

| Appearance | Perfectly smooth, seamless, mirror-like finish; hides minor substrate unevenness | Slightly rougher, “orange peel” effect; follows existing contours |

| Ease of App. | More complex, messier, requires specialized tools and expertise | Easier to apply, DIY-friendly, similar to painting |

| Durability | Better long-term resistance to wear and tear due to thickness | Good durability for lighter traffic, but less robust than self-leveling |

| VOCs | Tends to be 100% solids with no VOCs | Can vary, but often contains some VOCs |

What makes epoxy flooring self leveling?

The magic behind epoxy flooring self leveling lies in a carefully calibrated balance of chemistry and physics. As we mentioned, it’s all about how the material flows and cures.

When the two components (resin and hardener) are mixed, a chemical reaction begins. However, unlike standard epoxies, self-leveling formulations are engineered with specific additives – the aforementioned leveling agents. These agents drastically reduce the material’s viscosity, allowing it to flow freely, much like milk, rather than holding its shape like honey.

The principle of gravity then takes over. The low-viscosity liquid spreads out, seeking the lowest points and naturally forming a perfectly flat surface. Surface tension also plays a critical role; these formulations are designed to have low surface tension, which allows for an even spread and prevents “pooling” or “crawling” effects. The controlled working time, typically 30-60 minutes, ensures the material remains fluid long enough to level completely before the curing process advances too far and locks it into place.

The result is a floor that, once cured, is incredibly smooth and flat. This is a crucial distinction from standard epoxy coatings, which are generally less than 2 millimeters thick and simply coat the existing surface, reflecting any imperfections. Epoxy flooring self leveling, on the other hand, is applied at a minimum thickness of 2 millimeters, and often much more, enabling it to truly create a new, even surface.

Typical Applications and Industries

The versatility and robust nature of epoxy flooring self leveling make it an excellent choice for a wide array of environments, from residential spaces in West Vancouver to industrial complexes in Delta.

Residential Applications:

- Garages: Often plagued by uneven concrete slabs from settling, self-leveling epoxy can transform a bumpy garage floor into a perfectly smooth, durable, and chemical-resistant surface. It’s ideal for homeowners who want a clean, professional look and easy maintenance.

- Basements: Uneven concrete in basements is common, leading to pooling water and aesthetic issues. Self-leveling epoxy can fix these problems, creating a smooth, moisture-resistant barrier that’s ready for any finish, making your basement a truly usable space.

Commercial Applications:

- Showrooms and Retail Spaces: Aesthetics are paramount here. A high-gloss, seamless self-leveling epoxy floor provides a professional, modern, and attractive appearance that can improve product displays and customer experience. Its durability also stands up to heavy foot traffic.

- Offices and Lobbies: For a sleek, contemporary look that’s easy to maintain, self-leveling epoxy is a fantastic choice. It offers excellent durability and can be customized with various colors and finishes to match corporate branding.

Industrial Applications:

- Warehouses and Manufacturing Facilities: These environments demand extreme durability. Self-leveling epoxy provides perfectly level floors that are crucial for the efficient operation of manufacturing equipment, assembly lines, and material handling systems. It withstands heavy loads, forklift traffic, and constant abrasion, reducing equipment wear and improving safety.

- Food and Beverage Processing: The seamless, non-porous nature of self-leveling epoxy, especially with antimicrobial formulations, makes it ideal for maintaining strict hygiene standards. It resists harsh cleaning chemicals and prevents the accumulation of bacteria, meeting stringent health regulations.

- Pharmaceutical Plants and Laboratories: Similar to food processing, these facilities require sterile, easy-to-clean surfaces. Self-leveling epoxy provides chemical resistance and a seamless finish, crucial for preventing contamination and simplifying sanitation protocols.

- Healthcare Facilities: Hospitals, clinics, and veterinary offices benefit from the ease of sanitization and the durable, long-lasting nature of these floors.

No matter the application, the ability of epoxy flooring self leveling to provide a robust, seamless, and level surface makes it a superior choice for many of our clients across Metro Vancouver.

The Complete Guide to Applying Epoxy Flooring Self Leveling

Applying epoxy flooring self leveling is not a simple DIY project. While the “self-leveling” aspect might sound easy, achieving a professional, long-lasting finish requires meticulous preparation, precise mixing, and skilled application. This section covers the entire process from preparation to final cure, ensuring a professional-grade finish that will perform beautifully for years to come.

Step 1: Essential Substrate Preparation

We cannot stress this enough: surface preparation is the single most critical step for any successful resinous flooring system application. Without proper preparation, even the highest quality epoxy will fail. Our goal is to create a clean, dry, and properly profiled surface for maximum adhesion.

- Concrete Surface Profile (CSP 2-3): The concrete surface must have a suitable profile to allow the epoxy to “grip” it. We typically aim for a Concrete Surface Profile (CSP) of 2-3, which feels like 60-grit sandpaper. This is achieved through mechanical methods like grinding or shot-blasting. For new concrete, we ensure it has cured for a minimum of 28 days before any application.

- Cleaning and Degreasing: The floor must be impeccably clean, free from all contaminants such as oil, grease, paint, sealers, and dirt. We use industrial degreasers and thorough cleaning techniques, not just sweeping, to prevent “fish eyes” or crawling in the finished epoxy.

- Crack and Hole Repair: While self-leveling epoxy can smooth minor divots, larger cracks, holes, and gouges must be repaired before applying the epoxy. We fill these imperfections with appropriate repair materials to ensure a truly smooth and structurally sound base.

- Moisture Testing: This step is non-negotiable, especially for concrete slabs on or below grade (like basements). Moisture issues are a leading cause of epoxy floor failures, as trapped moisture can create pressure that delaminates the floor. We conduct moisture vapor transmission (MVT) tests, often using a calcium chloride test (ASTM F1869), to ensure MVT is 3 lbs. or less per 1000 sq. ft. in 24 hours. The concrete must also have a minimum tensile strength of 300 psi.

- Recommended Primers: A primer is essential for optimal adhesion and to seal the concrete, preventing outgassing (the release of air from porous concrete that can cause bubbles). We select primers based on the specific conditions of your floor, sometimes opting for moisture vapor barrier primers for floors with higher moisture readings. A low modulus epoxy primer is commonly used. The primer must be mixed precisely according to manufacturer instructions, typically with a working time of 20-25 minutes.

Step 2: The Application Process

Once the substrate is perfectly prepared and primed, it’s time for the main event: applying the epoxy flooring self leveling system. This is where precision and teamwork really come into play.

- Mixing Components: Epoxy flooring self leveling is a two-part system: Part A resin and Part B hardener. Accurate mixing is paramount for proper curing and performance. We use a mechanical mixer to thoroughly blend the two components at the manufacturer’s specified ratio (e.g., 2 parts base to 1 part hardener by volume, or 4 parts Part A to 1 part Part B). We mix slowly for about 3 minutes to avoid air entrainment. We only mix what can be applied within the pot life, which is typically 30-60 minutes at 72°F (22°C), but can be as short as 20 minutes at higher temperatures.

- Temperature and Humidity Control: The ambient, material, and substrate temperatures, as well as humidity, significantly impact the application and cure. Most systems perform best between 60-80°F (15-27°C). We ensure the substrate temperature is at least 5°F (3°C) above the dew point to prevent condensation, and relative humidity is 85% or less.

- Pouring in Ribbons: Once mixed, the material must be applied quickly. We pour the mixed epoxy onto the primed floor in ribbons. This helps distribute the material evenly and efficiently across the surface.

- Spreading with Notched Squeegee: Immediately after pouring, we use a flat or notched rubber squeegee to spread the material to a uniform thickness. The notches on the squeegee help control the thickness of the applied epoxy.

- Using Spiked Tools: This is where the fun begins, and where expertise truly shines! To work on the wet epoxy without leaving footprints, our team wears spiked shoes. As the material is spread, air can become trapped, leading to bubbles. We use a spiked roller, also known as a porcupine roller, to gently roll over the wet surface. This releases trapped air bubbles, ensuring a smooth, flawless finish. We typically roll within 15 minutes of application, but never after 30 minutes, as the material starts to tack up.

- Back-Rolling Technique: After spreading, we perform a final “back-rolling” or “tipping off” with a lint-free roller, uniformly in one direction. This helps to even out any squeegee marks and further improve the surface appearance.

- Recoat Windows and Cure Times: Adhering to recoat windows is crucial for proper inter-coat adhesion. Minimum recoat times can be around 16 hours, with maximums typically within 24 hours. If this window is exceeded, the surface may need to be abraded before applying another coat.

- Dry to Touch: 8-12 hours at 72°F.

- Dry to Walk On (Light Traffic): 24 hours at 72°F.

- Resistant to Vehicular Service: 3 days at 72°F.

- Full Chemical Cure: This is when the floor achieves its maximum hardness and chemical resistance, typically taking 7 days at 55°F (13°C).

- Large-Scale Project Considerations: For large commercial or industrial projects across Surrey, Richmond, or Port Coquitlam, planning is key. Due to the limited pot life, we often work in sections, planning boundaries along natural divisions or using controlled joints. Professional installers often mix large batches using dedicated mixing equipment to maintain consistency. Team coordination is essential, with members performing simultaneous tasks to ensure the entire area is covered efficiently before the epoxy begins to cure.

Compared to roller-applied epoxy, the application of epoxy flooring self leveling is definitely more complex and requires a higher level of skill and specialized tools. Roller-applied epoxies are considered more DIY-friendly, but for a truly flawless, thick, and durable floor, self-leveling demands professional expertise.

Troubleshooting and Advanced Techniques

Even with the best intentions and preparation, issues can sometimes arise during epoxy flooring self leveling installations. But don’t worry, we’ve encountered them all and know how to avoid them or address them if they pop up. This section addresses common issues and how to achieve specific performance characteristics for your floor.

Common Problems with Epoxy Flooring Self Leveling and How to Avoid Them

- Fish Eyes and Crawling: These are small, circular craters or areas where the epoxy pulls away from the surface, resembling fish scales.

- Cause: Usually caused by surface contamination (oil, grease, silicone, waxes) or sometimes by moisture.

- Avoidance: Meticulous cleaning and degreasing of the substrate are paramount. We always ensure the floor is spotless before priming.

- Uneven Thickness: Despite being “self-leveling,” if the underlying substrate has significant slopes or deep depressions, the epoxy might not appear perfectly uniform.

- Cause: Major variations in the concrete slab’s levelness.

- Avoidance: For severely uneven floors, we address major levelness issues and fill large low spots with a leveling compound before applying the self-leveling epoxy. This ensures a consistent thickness and truly flat final surface.

- Bubbles and Pinholes: Small craters or bubbles can appear on the surface, often due to trapped air or outgassing from the concrete.

- Cause: Porous concrete releasing air (outgassing) during curing, improper mixing (too fast), or not using a spiked roller.

- Avoidance: Proper priming is crucial to seal porous concrete. We also use a spiked roller immediately after spreading the epoxy to release trapped air. Mixing slowly and thoroughly also prevents air entrainment.

- Slow Cure or Soft Spots: Areas of the floor that remain tacky or soft even after the expected cure time.

- Cause: Incorrect mix ratio (most common), low ambient or substrate temperature, or inadequate mixing.

- Avoidance: Accurate measurement and thorough mixing of Part A and Part B are critical. We ensure ambient and substrate temperatures are within the manufacturer’s recommended range (typically 60-80°F) throughout the application and initial cure.

It’s worth noting that fixing problems with self-leveling epoxy is much more involved than with roller-applied systems. If a defect occurs with a thin roller-applied coating, it can often be fixed by applying another thin coat. However, with epoxy flooring self leveling, fixing defects usually requires recoating the entire surface at its minimum 2mm thickness again, which means significant material and labor costs. This is another reason why professional installation by experienced teams like ours is so valuable.

Enhancing Performance and Safety

Beyond the standard smooth finish, we can further customize epoxy flooring self leveling to meet specific performance and safety requirements.

- Slip Resistance Management: A perfectly smooth, high-gloss epoxy floor can be slippery, especially when wet. To improve safety, particularly in commercial kitchens, industrial facilities, or public spaces in New Westminster, we offer several options:

- Texture Additives: Fine aggregates can be mixed directly into the final epoxy layer or topcoat.

- Broadcast Media: While the epoxy is still wet, we can broadcast media like silica sand or aluminum oxide onto the surface. Once cured, the excess is swept away, and a clear topcoat seals in the texture. This creates a highly effective skid-inhibiting finish.

- Anti-Slip Topcoats: Specialized topcoats with integrated anti-slip properties can be applied.

- Polyurethane Topcoats: While epoxy is incredibly durable, a polyurethane topcoat can provide additional benefits, creating a hybrid system that offers the best of both worlds.

- UV Resistance: Epoxy can sometimes yellow over time when exposed to UV light (e.g., direct sunlight through windows or garage doors). Polyurethane topcoats offer superior resistance to UV yellowing, maintaining the floor’s aesthetic appeal for longer.

- Abrasion Resistance: Polyurethane often provides even better abrasion resistance than epoxy, making it ideal for extremely high-traffic areas or environments with heavy machinery.

- Chemical Resistance: Certain polyurethane formulations can improve the floor’s resistance to specific chemicals, further safeguarding the surface.

We recommend polyurethane topcoats for areas that will see significant sunlight exposure or require the absolute highest level of wear resistance.

For those venturing into epoxy for the first time, it’s generally a good idea to start with roller-applied epoxies. As we’ve emphasized, epoxy flooring self leveling is a more advanced application that benefits greatly from experience. If you are new to epoxy, start with roller applied epoxies.

Maintenance and Longevity

One of the great advantages of epoxy flooring self leveling is its impressive longevity and relatively low maintenance requirements. Properly installed, these floors can last anywhere from 10 to 20 years in most applications, providing excellent value over their lifespan.

To ensure your self-leveling epoxy floor looks its best and lasts for decades, here are our maintenance recommendations:

- Daily Cleaning: For general cleanliness, regular dust mopping or sweeping is usually sufficient to remove loose debris. For a deeper clean, occasional mopping or mechanical scrubbing with a soft bristle brush and a mild, surfactant-type cleaner works wonders. Many systems are robust enough to withstand harsh industrial cleaning solutions, making them suitable for demanding commercial and industrial settings in Maple Ridge or Coquitlam.

- Prompt Spill Cleanup: Although epoxy floors are highly resistant, it’s always best to clean up spills promptly. This prevents potential staining or prolonged exposure to harsh chemicals that, over time, could affect the surface.

- Scratch Prevention: While highly durable, no floor is entirely scratch-proof. We recommend using felt pads under furniture legs, using appropriate wheels on carts and equipment, and placing entrance mats at doorways to trap abrasive dirt and grit from outside.

- Periodic Recoating: To further extend the life of your floor and refresh its appearance, a periodic recoating can be beneficial. Applying a fresh topcoat every 5-10 years can refresh the surface, repair minor surface wear, and add another layer of protection, making your floor look brand new again.

With these simple maintenance practices, your epoxy flooring self leveling will continue to provide a beautiful, functional, and long-lasting surface for many years.

Conclusion

Epoxy flooring self leveling offers a transformative solution for anyone seeking a flawless, durable, and low-maintenance floor. From its unique chemical properties that allow it to flow and level perfectly, to its ability to hide concrete imperfections and offer a vast array of aesthetic and specialized performance options, it truly stands out as a superior flooring system.

We’ve explored how it differs from standard coatings, its diverse applications in residential, commercial, and industrial settings, and the critical steps involved in preparation and application. We’ve also armed you with insights into avoiding common pitfalls and enhancing your floor’s safety and performance with features like slip resistance and polyurethane topcoats. The longevity and ease of maintenance further solidify its position as an excellent long-term investment.

Achieving a truly exceptional epoxy flooring self leveling finish, however, hinges on meticulous preparation, precise mixing, and expert application techniques. It’s a job where experience makes all the difference, ensuring that your floor performs as designed and lasts for decades.

For a guaranteed professional result on your next epoxy flooring self leveling project in Vancouver, Burnaby, Richmond, or anywhere across Metro Vancouver, trust the experts at Fraser Plus Epoxy. We bring 10 years of experience and a commitment to exceptional customer satisfaction to every job, delivering durable, aesthetically pleasing, and long-lasting floor coatings custom to your specific needs.

Contact us today to discuss your vision and let us help you achieve a truly flawless floor. Contact us for your epoxy flooring project.