Industrial environments demand robust epoxy flooring solutions that can withstand extreme conditions. Epoxy flooring has emerged as a critical technology, transforming how different sectors manage their ground-level infrastructure.

Studies shown that industrial epoxy flooring systems can reduce maintenance costs by up to 40-60% in manufacturing environments, providing significant long-term financial benefits for businesses. From manufacturing plants to food processing facilities, these advanced flooring systems offer more than just a surface—they provide a strategic performance platform.

The Manufacturing Sector’s Flooring Revolution

Manufacturing plants face brutal daily challenges. Heavy machinery, constant foot traffic, and potential chemical spills create a harsh environment where ordinary flooring quickly deteriorates. Epoxy systems have changed this narrative, delivering exceptional durability that resists mechanical stress and chemical exposure.

Our research shows that epoxy floors in manufacturing settings can reduce maintenance costs by up to 40% compared to traditional concrete or tile surfaces. The seamless installation prevents dust accumulation and creates a smoother working environment, which indirectly improves worker productivity and safety.

Key Performance Attributes:

- Chemical resistance to industrial solvents

- Skid-resistance for enhanced workplace safety

- Reduced maintenance requirements

- Improved production efficiency

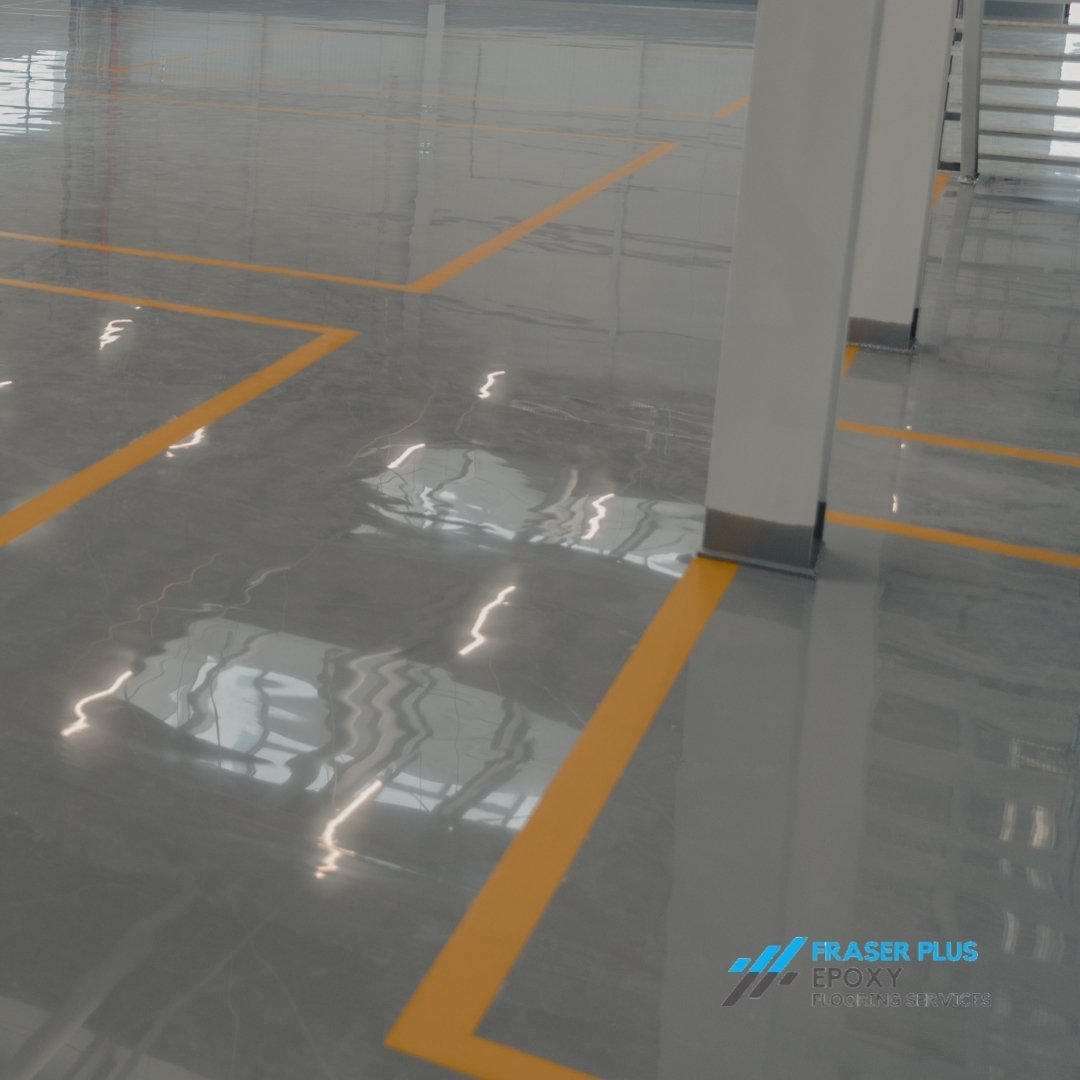

Automotive Industry

The automotive sector demands flooring that matches its precision engineering. Epoxy systems in these environments must withstand constant movement of heavy equipment, resist automotive fluid spills, and maintain a clean, professional appearance.

High-gloss epoxy surfaces not only enhance workplace aesthetics but also improve lighting reflection, creating a brighter, more efficient workspace. Case studies from leading automotive manufacturers demonstrate that these floors maintain structural integrity even after two years of intense use, significantly reducing long-term replacement costs.

Food and Beverage

Food processing facilities have the most stringent flooring requirements. Epoxy systems here are not just about durability—they’re about maintaining critical hygiene standards. The seamless, non-porous surface prevents bacterial growth and allows for thorough, efficient cleaning.

Facility managers must consider factors like:

- Chemical exposure levels

- Traffic intensity

- Temperature variations

- Cleanliness standards

- Potential impact damage risks

Regulatory compliance is paramount in this sector. Epoxy floors meet FDA and USDA standards, providing a surface that can be quickly sanitized and resists microbial contamination. This makes them an essential investment for facilities prioritizing food safety and quality control.

Warehouse and Logistics

Warehouses represent a unique challenge with constant movement of heavy equipment and substantial load-bearing requirements. Epoxy flooring systems here must provide stability, resistance to wear, and safety features that protect both equipment and personnel.

Anti-slip additives in epoxy formulations reduce workplace accidents, while the surface’s ability to withstand heavy forklift traffic ensures long-term performance. Studies indicate that properly installed epoxy floors can reduce surface damage by up to 60% compared to traditional concrete surfaces.

Industrial Epoxy Flooring: Comparative Performance Metrics

| Sector | Durability | Chemical Resistance | Maintenance Ease | Safety Features |

| Manufacturing | High | Excellent | Low | Moderate |

| Automotive | Very High | Excellent | Low | High |

| Food Processing | High | Excellent | Very High | Very High |

| Warehousing | High | Moderate | Moderate | High |

The Economic and Performance Advantage

Vancouver’s industrial landscape demands high-performance flooring coating solutions that deliver both economic efficiency and exceptional durability. Epoxy flooring systems provide businesses with a strategic investment that dramatically reduces long-term maintenance costs while enhancing workplace safety and operational performance.

The true value of epoxy flooring lies in its comprehensive benefits:

- Reduced maintenance costs

- Enhanced workplace safety

- Improved aesthetic and functional performance

- Long-term durability

A Strategic Infrastructure Investment

Epoxy flooring represents more than a surface upgrade—it’s a strategic investment in industrial infrastructure. By providing tailored solutions that balance performance, safety, and economic efficiency, these systems are reshaping how industries approach their foundational environments.

As industrial technology continues to advance, Fraser Plus Epoxy remains committed to delivering cutting-edge flooring solutions that meet the evolving needs of diverse sectors. Our team’s expertise ensures businesses receive not just a floor coating, but a comprehensive performance upgrade that supports long-term operational excellence.

FAQs

- How long does epoxy flooring typically last in industrial settings?

Industrial epoxy flooring can last 10-40 years with proper installation and maintenance, depending on traffic intensity and environmental conditions. The durability varies across different industrial sectors, with some high-performance applications extending beyond standard expectations.

- Can epoxy flooring be customized for specific industry requirements?

Epoxy flooring offers extensive customization options, including specialized formulations for chemical resistance, thermal stability, and anti-slip properties. Manufacturers can develop unique blends tailored to specific industrial environments, ensuring optimal performance for each sector’s unique challenges.

- What are the installation time requirements for industrial epoxy flooring?

Typical industrial epoxy floor installation takes 3-5 days, including surface preparation, coating application, and curing time. The precise timeline depends on the floor area, specific formulation, and environmental conditions during installation.

- How environmentally friendly are modern epoxy flooring systems?

Modern epoxy flooring systems are increasingly eco-friendly, with low VOC emissions and potential for recycling at the end of their lifecycle. Many manufacturers now incorporate bio-based resins and sustainable production techniques to minimize environmental impact.

- What maintenance practices extend epoxy flooring lifespan?

Regular cleaning with non-abrasive methods, prompt spill management, and annual professional inspections can significantly extend epoxy flooring performance. Avoiding harsh chemical cleaners and using recommended maintenance protocols helps preserve the floor’s integrity and appearance.

People Also Ask

- How do temperature changes affect epoxy flooring performance?

Epoxy flooring is designed to withstand significant temperature fluctuations without compromising structural integrity. High-quality industrial epoxy systems can maintain performance in environments ranging from -20°F to 200°F, making them suitable for extreme industrial conditions.

- Can epoxy flooring be applied over existing damaged concrete?

Professional epoxy installers can repair and prepare damaged concrete surfaces before applying the coating, ensuring a smooth and durable finish. However, extensive concrete damage may require complete surface restoration or replacement before epoxy application.

- What are the uv resistance properties of industrial epoxy flooring?

Standard industrial epoxy floors can yellow or degrade when exposed to direct sunlight for prolonged periods. Specialized UV-resistant epoxy formulations are available for areas with high sun exposure, providing enhanced color stability and longevity.

- How quickly can industrial epoxy flooring be installed?

Professional epoxy floor installation typically takes 3-5 days, including surface preparation, coating application, and curing time. The exact timeline depends on the floor area, specific environmental conditions, and the complexity of the project.

- Are there eco-friendly epoxy flooring options?

Modern epoxy flooring manufacturers are developing low-VOC and sustainable resin systems that minimize environmental impact. Some advanced formulations now incorporate recycled materials and bio-based resins to improve ecological sustainability.