Converting your Garage into a Welcoming and Professional-Looking Area.

Get Your Free Epoxy Flooring Estimate Today!

You can also call us and speak with our epoxy floor expert at 778-952-0221.

ADVANTAGES:

A residential garage floor with properly applied epoxy and polyaspratic floor coatings is a great feature that is very beneficial to residential properties and is also a great investment. It will function as a powerful, long-lasting anti-dust sealer and instantly turn your garage floor into a welcoming space, but choosing the correct contractor is essential.

We acknowledge that not everyone will be a good fit for garage epoxy floor, but at the end of this page, you will know all you need to know to make an informed choice about which contractor to hire for your garage floor coating project. You’ll also know what questions to ask and where to look for long-lasting garage floor coating options that are installed correctly.

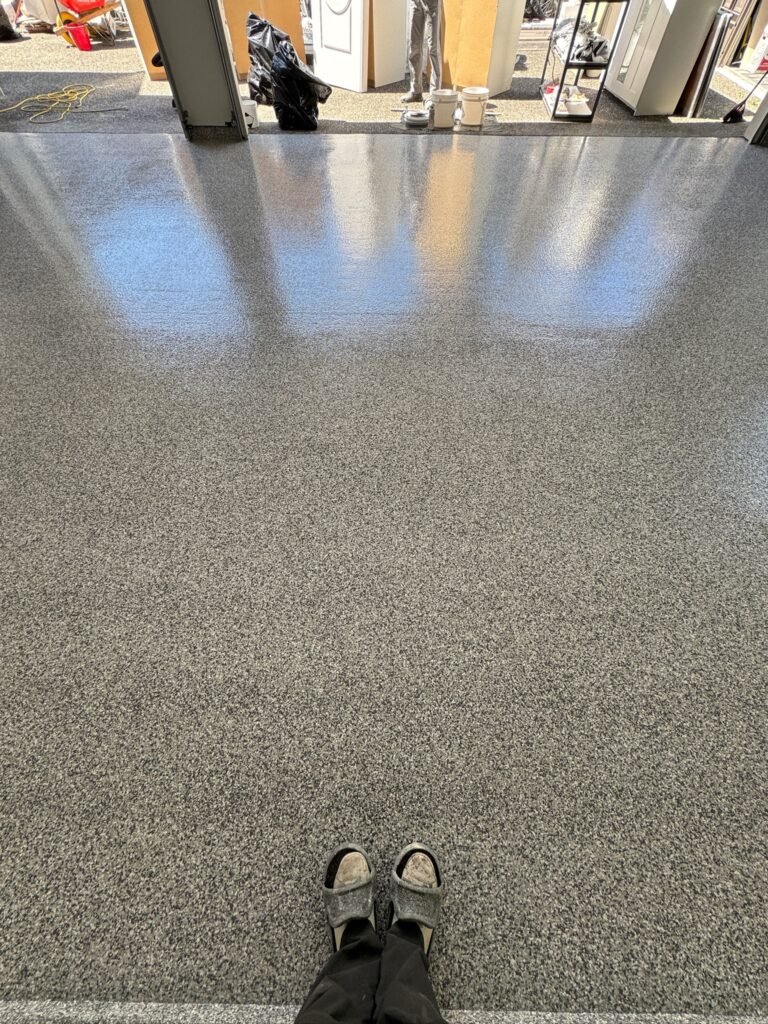

To see pictures of our completed projects in different color schemes and system configurations, please scroll to the bottom of the page.

Your property’s worth will rise if you install an industrial-grade floor coating system on your garage floor. The Sydney median house can cost up to 1.1 million dollars, so if you make your garage floor more attractive, you can raise the property’s value and showcase the building’s excellence. High-build epoxy mortars make it simple to repair stained or damaged concrete, and our proprietary SEF premium designs can be applied on top.

Transform your garage with durable and stylish garage floor epoxy from Fraser Plus Epoxy. Our high-quality epoxy coatings provide a seamless, easy-to-clean surface that enhances the look and functionality of your space. Whether you’re looking for a sleek finish or extra protection, our garage floor epoxy solutions are designed to last.

When properly placed, a two-pack floor coating system is extremely durable and protects your garage floor from hot tire pick-up, fuel, and oil. For any garage floor covering, our SEF Premium Flake System with a polyaspartic topcoat is the ideal option. With its superior UV-resistant polyaspartic finish, you can be sure that it will be adequately preserved for many years to come, allowing you to relax!

Epoxy coating allows you to permanently seal your concrete and eliminate worry—managing your garage floor can be a tedious task! The epoxy will form a barrier, making it possible to live a hassle-free life rather of spending hours cleaning up dust. Furthermore, it does away with dusting, which saves you even more time when cleaning your house. Think about applying an epoxy coating—it might be the long-term fix you’ve been searching for!

Our floor coating solutions can be cleaned or pressure washed, and they require very little upkeep to stay clean.

LOW VOC products are safe for you and your family to use, easy to breathe, and have a short-lived odor that dissipates over time.

There is something for every taste in our exclusive and contemporary designs, which have been created to satisfy contemporary design standards.

The longest floor coating job’s lifespan is primarily determined by proper preparation. The epoxy resin will not be anchored into the subfloor if the concrete is not correctly prepared, and it will break quickly.

With PROPER Floor preparation equipment, we can use diamond grinding as our approved way of preparation for GARAGE FLOOR EPOXY COATING. Fraser Plus Epoxy Floors does not recommend acid etching, pressure washing, or other comparable preparation methods. Although the finished product may seem the same, the coating is susceptible to chipping when exposed to heat and pressure, especially on automobile tires. Our fleet of specially designated garage floor coating vehicles is outfitted with the most recent floor preparation tools and dust extractors of the highest caliber.

The level of experience and product knowledge of an applicator play a significant role in the final outcome of your floor coating product. The industry is currently oversupplied with unskilled applicators and lacking in industrial coating applicators as a result of decreased demand in other industries.

In order to uphold Fraser Plus Epoxy’s industry-leading reputation, all members of our garage floor coating team must possess the utmost skill and training, as well as a minimum of five years of experience in the field of garage floor coating. This experience is essential for making informed decisions and carrying them out promptly.

Floor coating materials are offered in high, mid, and low quality, just like any other product on the market.

Although there is a large variety of epoxies on the market and most paint manufacturers would like to take a cut, NOT ALL EPOXIES ARE THE SAME.

COATING OF GARAGE FLOOR Three grades of epoxies and clear products are available:

1. HIGH GRADE: These products are typically 20–25% more expensive than the second-best-ranked brands and are created and sold by well-known businesses.

They are safe for you and your family to use and kind to the environment. We promise both to you and our employees that we will exclusively utilize premium-grade products and we like to contribute in some small way to ensure that our planet is preserved for future generations.

2. Contractor Grade: The majority of contractors strongly prefer this level. They typically smell strongly and are less expensive. These potent smells can cause respiratory problems and are quite dangerous. They can linger in your home for a long time. Like asbestos, we firmly think that these goods ought to be outlawed by the government.

3. DO-IT-YOURSELF PRODUCTS: These items can be found in hardware and paint stores. The primary goal in creating these epoxies is to “Be Easy to Apply.” To this end, a lot of thinning agents, like water or solvents, are added to the mixture. The end result is a product that is marginally superior to paving paints.

A product’s quality is greatly influenced by the thickness of the dry film, which is measured in microns (1000 microns = 1 mm). Adding thinners or water will improve product coverage and drastically lower the cost of the material, but the finish quality will suffer as a result.

For a premium finish that lasts up to 15 years, a suitable garage floor flake epoxy coating should include between 400 and 600 microns of clear topcoat. Applying four applications of typical polyurethanes is necessary to reach a dry film thickness of 400 microns. Using a squeegee, we apply our Ultra-premium UV Resistance EPOXY clear top coat. We pledge to provide the thickness that will deliver durability for your garage epoxy flooring system.

This isn’t just a marketing ploy. Let the honest reviews of our highly satisfied customers tell you our story.

EXCELLENTTrustindex verifies that the original source of the review is Google. We really enjoy working with Sunny. He was patient with the client and made sure that we have a clear idea idea of the job before proceeding. Job well done!Posted onTrustindex verifies that the original source of the review is Google. They did a great job and the my garage floor looks amazing. Would definitely recommend.Posted onTrustindex verifies that the original source of the review is Google. I am very pleased with the work they did for Empire Abbotsford Recycled Auto & Truck Parts. We put down an epoxy flooring, and it looks absolutely amazing. The price is unbeatable, and it did not take them long to do, plus great warranty! Highly recommend and would definitely use them again!Posted onTrustindex verifies that the original source of the review is Google. Fraser Plus Epoxy did a great job epoxy coating my garage floor. The results were beyond my expectations. They are very detail oriented and I just couldn't find any bad spots anywhere on the floor. What pushed the job beyond my expectation were their accurate estimations and clear explanation of the process. Sunny was always on time and finished the job before ETA. I would highly recommend their services if anyone is looking for any kind of epoxy coating for their floors.Posted onTrustindex verifies that the original source of the review is Google. Amazing work by Sunny and great outcome and well priced.I got my brand new garage epoxy floor done.He was on time and completed on schedule. Quality of work was very nice.I will recommend him for this kind of workPosted onTrustindex verifies that the original source of the review is Google. Great, on time, good work!Posted onTrustindex verifies that the original source of the review is Google. Excellent customer dealingPosted onTrustindex verifies that the original source of the review is Google. Highly recommend Fraser plus epoxy for all your epoxy needs. Very good to deal with and very competitive prices. We will be using them on all future projects.